10. STANDARD ADJUSTMENTS

43

KE-434C,435C

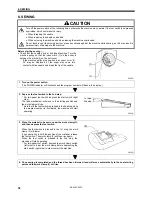

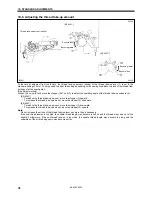

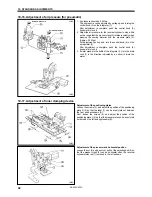

10-9. Work clamp interchangeability

The BAS-311F work clamp can also be used with the KE-

434C, 435C.

Replace the feed bar guide cover (1) with the feed bar guide

cover assembly, LL (2) (optional).

Then, change the installation position for the presser arm

assembly (3) from the standard installation position A to

installation position B.

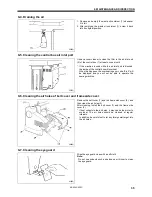

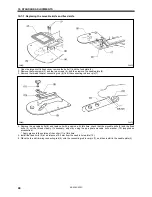

To use the BAS-311F work clamp and the KE-434C, KE-

435C work clamp interchangeably

Use the optional work clamp 434EMK2 air (5) with the KE-

434C, KE-435C work clamp.

It can then be used interchangeably with the BAS- 311F work

clamp (6) at installation position B.

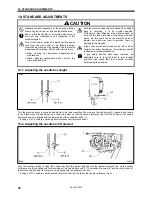

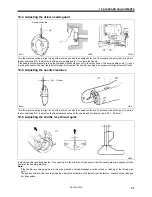

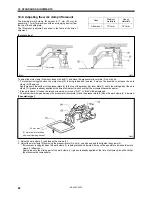

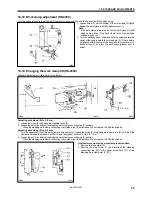

10-10. Adjusting the needle up stop position

The needle up stop position is adjusted so that the index

mark (2) on the machine pulley (1) is inside the mark (4) on

the belt cover (3).

If adjustment is necessary, loosen the screw (5) at the “U”

mark of the machine pulley (1) and adjust the position of the

machine pulley (1). The machine pulley (1) stops later if it is

turned clockwise, and it stops earlier if it is turned counter-

clockwise.

Note:

The screw (6) at the “D” mark is an adjusting screw for the

needle down detection function and is adjusted to match

the feed timing, so it should not be loosened.

The screw (7) is a screw for detecting the machine stop

position, and should not be loosened.

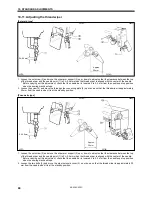

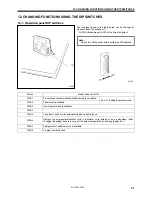

* If the index mark (2) is not inside the mark (4) when the

sewing machine is started, error code “E-50” will be

displayed. Turn the machine pulley to move the index mark

(2) to the correct position and then start the sewing

machine.

2619Q

2620Q

2576Q