10. STANDARD ADJUSTMENTS

37

KE-434C,435C

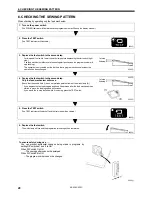

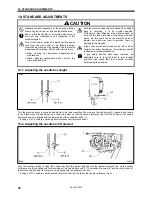

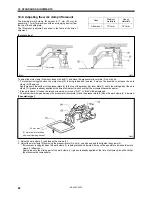

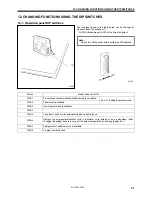

10-3. Adjusting the driver needle guard

Turn the machine pulley to align the tip of the rotary hook with the needle center line. Then loosen the set screw (2) and turn

the eccentric shaft (3) to adjust so that the driver needle guard (1) contacts the needle.

If the needle contact pressure is too great, skipped stitches may occur. On the other hand, if the driver needle guard (1) is not

touching the needle, the tip of the inner rotary hook will obstruct the needle, resulting in an excessively high amount of friction.

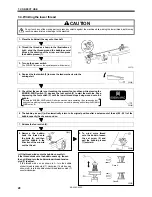

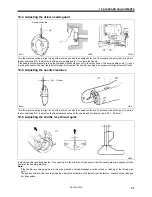

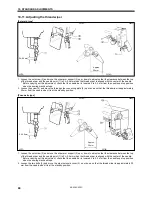

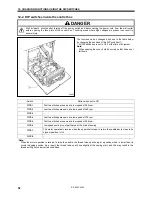

10-4. Adjusting the needle clearance

Turn the machine pulley to align the tip of the rotary hook with the needle center line. Then loosen the set screw (1) and turn

the eccentric shaft (2) to adjust so that the clearance between the needle and the rotary hook is 0.01 - 0.08 mm.

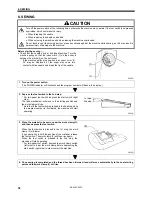

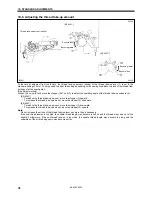

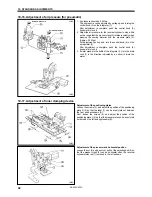

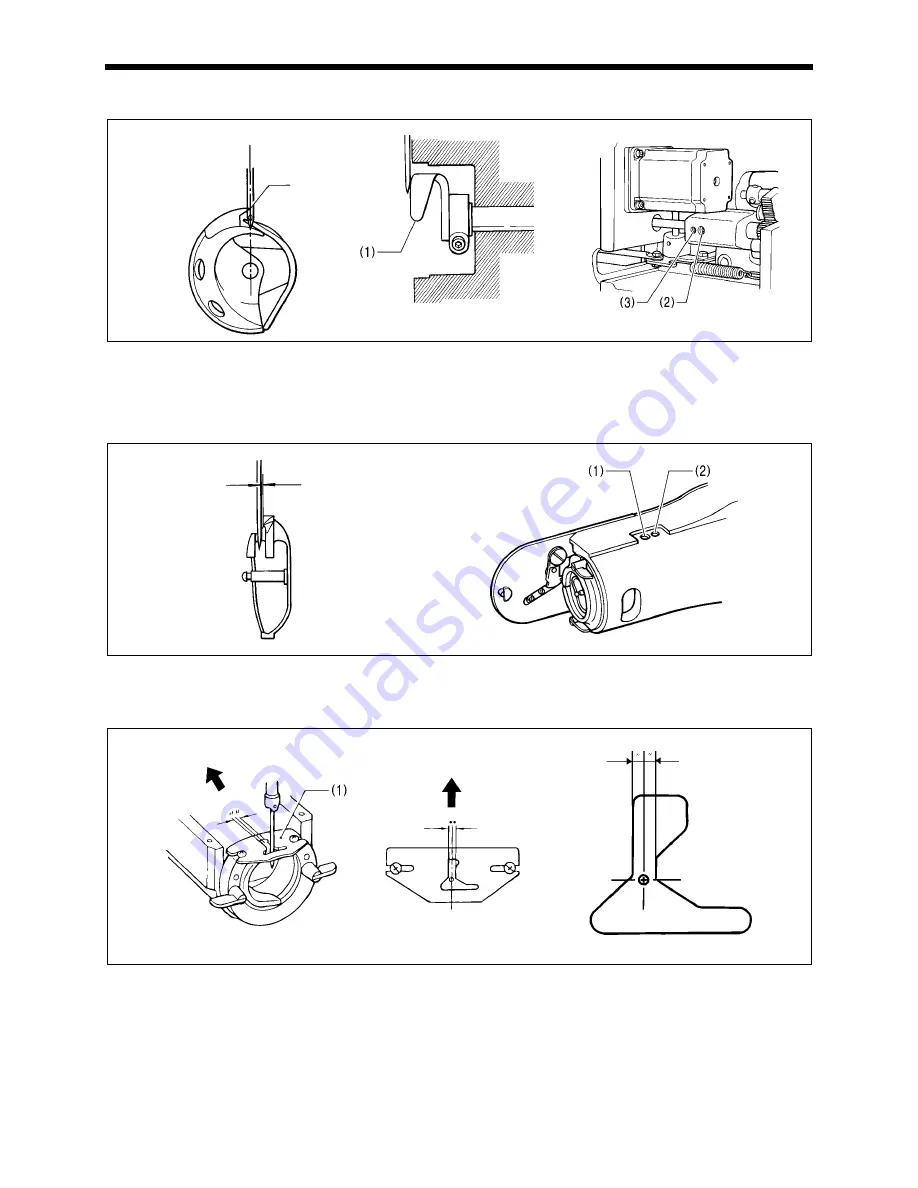

10-5. Adjusting the shuttle race thread guide

Install the shuttle race thread guide (1) by pushing it in the direction of the arrow so that the needle groove is aligned with the

center of the needle plate hole.

Note:

If the shuttle race thread guide is in the wrong position, thread breakages, soiled thread or catching of the thread may

occur.

The position of the shuttle race thread guide is adjusted at the time of shipment from the factory. It should not be changed

if at all possible.

0135Q

Needle center line

Tip

2555Q

2556Q

0138Q

2557Q

0.01 - 0.08mm

2558Q