200768_1

19

Trouble-shooting

The gas pilot will not ignite or stay lit

Ensure the gas is turned on at the appliance and the meter / cylinder.

Is there a strong spark being generated, check connections if not.

The pilot gas button must be held in for at least 20 seconds once the pilot is

established to ensure the safety thermocouple is heated sufficiently.

Ensure that both ends of the TTB connection cable are firmly connected. Instruction

for connecting the TTB is given earlier in this instruction (page 9). You can also rule

out a faulty TTB sensor by connecting the two ends of the TTB connection wire

together using a metal paper clip.

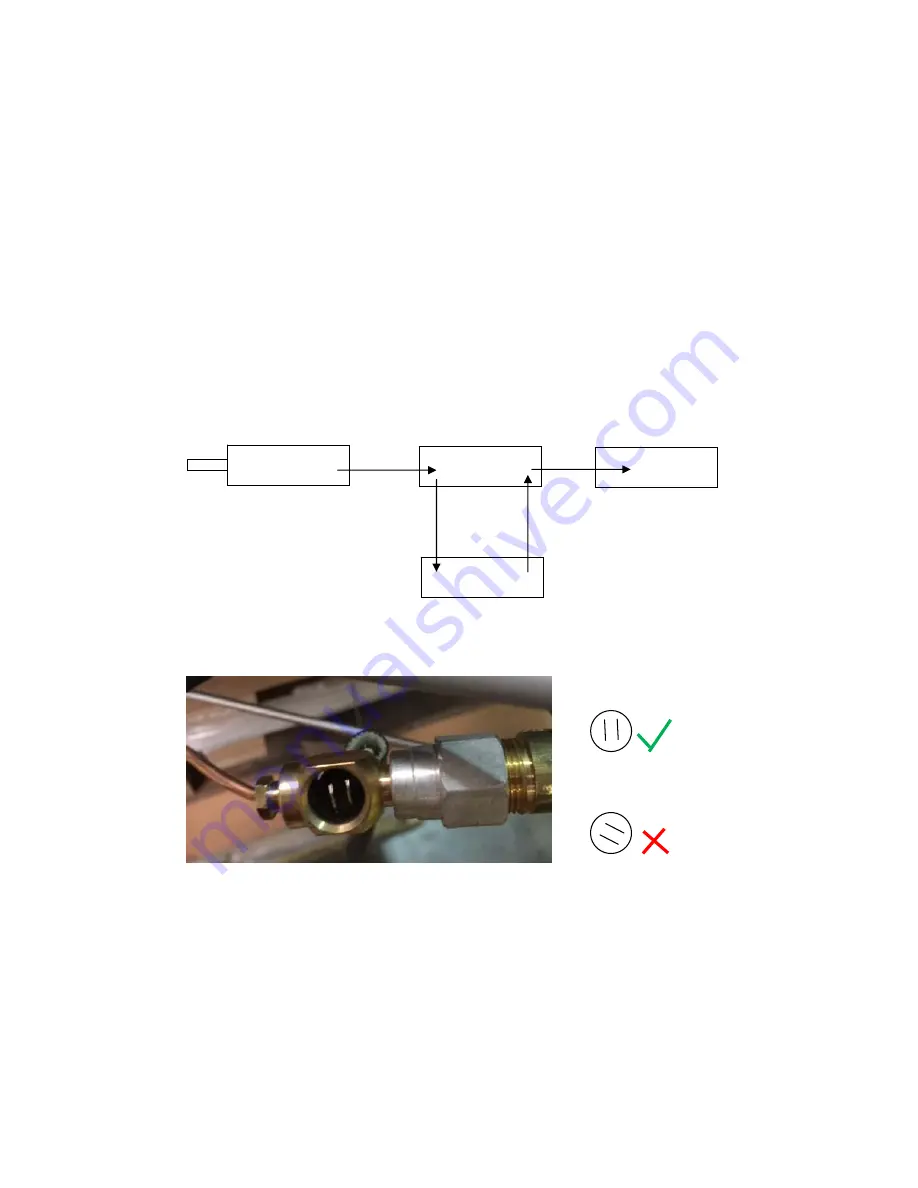

Make sure that the brass interrupter (connects thermocouple and TTB to valve –

shown on page 9) is not too loose. You should not be able to move the interrupter by

hand. Any break in the following circuit will cause the pilot not to stay alight as the

electrical charge from the thermos-couple needs to arrive at the valve to keep it lit:

Take care not to overtighten the interrupter unit into the valve as this can twist the

spade connections. As you look at the back of the interrupter the spade connections

should look like two vertical lines (if they are more like 45°C then its too tight)

Ensure that the pilot injector is not obstructed or blocked and it is free from any dust

or dirt.

Ensure gas pressures and flow rates are correct, as this will prevent ignition of the

pilot. An indication of high pressure can be a whistling sound from the pilot.

Ensure that the pilot assembly has not been damaged in transit. Be sure to check the

gap between the thermocouple and electrode is sufficient and that the spark is not

arcing elsewhere, this is a very delicate device.

The pilot flame should burn with a strong blue flame. The flame should be focused

on the tip of the thermocouple.

Thermocouple

TTB Sensor

Interrupter

Valve