2-3

Brooks

®

Models 5964, 5850EM

Section 2 Installation

Installation and Operation Manual

X-TMF-5964-5850EM-MFC-eng

Part Number: 541B121AHG

November, 2008

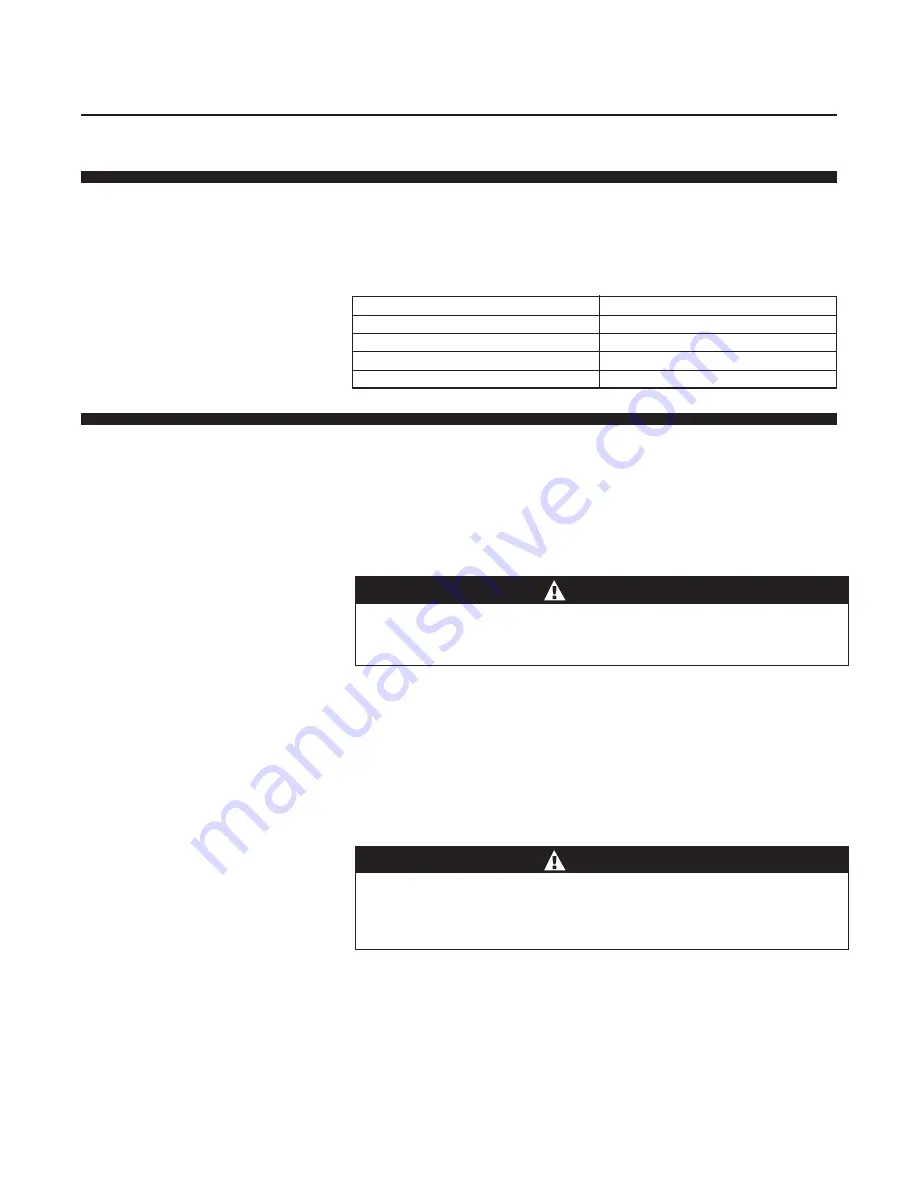

2-7 In-Line Filter

It is recommended that an in-line filter be installed upstream from the

controller to prevent the possibility of any foreign material entering the

flow sensor or control valve. The filtering element should be replaced

periodically or ultrasonically cleaned.

Maximum Flow Rate

Recommended Filter

100 sccm

1 micron

500 sccm

2 micron

1 to 5 slpm

7 micron

10 to 30 slpm

15 micron

2-8 Installation

Prior to installation, make certain all piping is clean and free of

obstructions, for tubing installations. Install the piping in such a manner

that permits easy access to the instrument if it needs to be removed for

cleaning or test bench troubleshooting. For surface mount (downported)

devices verify that the seal cavities are clean and free of lateral

scratches.

When installing the controller, care should be taken that no

foreign materials enter the inlet or outlet of the instrument. Do not

remove the protective end caps until time of installation.

CAUTION

Recommended installation procedures:

a. The Model 5964/5850EM should be located in a clean, dry atmo-

sphere relatively free from shock and vibration.

b. Leave sufficient room for access to the electrical components, span

and zero potentiometers.

c. Install in such a manner that permits easy removal if the instrument

requires servicing.

When used with a reactive (sometimes toxic gas) contamination

or corrosion may occur as a result of plumbing leaks or improper

purging. Plumbing should be checked carefully for leaks and the

instrument purged with clean, dry N

2

before use.

CAUTION

d. The Model 5964/5850EM Mass Flow Controller can be installed in

any position. However, mounting in orientations other than the

original factory calibration (see calibration data sheet) can result in a

0.5% maximum full scale shift after re-zeroing.

Table 2-1 Recommended Filter Size