5

Section A – Installation

Your compactor has been designed to require minimum

space without loss of capacity whether free-standing or

built-in.

Free-Standing

As shipped, the compactor is only configured for built-in

installations. This appliance can be converted from built-

in to free-standing with the use of Toe Kick Accessory Kit

Model 15TCTK (sold separately).

If additional cord length is required for free-standing

installation, remove the cord clamp and wire tie on the

back of the unit.

CAUTION

Failure to use Toe Kick Assembly Kit Model 15TCTK in

a free-standing installation may cause the compactor

to be unstable during operation.

Built-in Installation

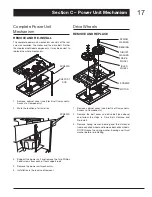

MOUNTINg STRAPS

TOP OF

COMPACTOR

FRONT OF

COMPACTOR

Two under-counter mounting straps are provided. Use

these straps to secure the compactor to the underside

of a countertop.

Fasten the slotted end of the straps to the compactor

using the holes in the top of the compactor cabinet as

shown.

NOTE: When installation compactor under granite or

solid surface countertops, bend the mounting straps so

they can be secured to the adjacent cabinetry.

UNDER-COUNTER OPENINg

Opening

15" Wide

34-1/2" High

22" Deep

15" W

34

1

/

2

" H

22" D

12" MIN

ELECTRICAL

OUTLET

The compactor requires an under-counter opening 15-in.

wide, 34-1/2-in. high, and 22-in. deep.

Plan to provide an electrical outlet in the opening that

meets all applicable electrical codes and requirements.

See “Grounding Instructions” on Page 2 for specific

information.