58

[email protected]

www.boschert.de

Mattenstraße 1

79541 Lörrach-Hauingen

Tel.: +49 (0) 7621 - 95 93 0

Fax: +49 (0) 7621 - 55 18 4

Changes reserved

Version: 01/ 2004

12.11

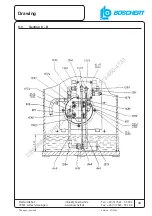

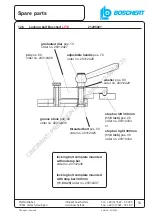

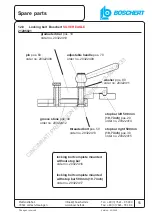

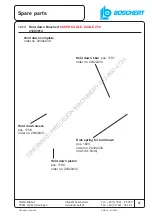

Mini stop (optional)

21205007

Mini stop

order no. 20310001

Spare parts

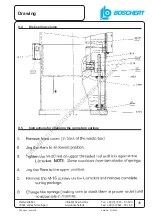

Sample for mini stops to avoid aditional

setting of the standard stops.