|

33

Installation Instructions

Singular Combi Boiler - BTC 439003301 B (2021/07)

6.2 Vent Pipe Materials

WARNING:

Venting requirements differ in the US and Canada. Consult

the following chart or the most recent edition of ANSI

Z223.1/ NFPA 54 or CAN/CGA B149.1, as well as all

applicable local codes and regulations when selecting vent

pipe materials. Do not use cellular core PVC (ASTM F891),

cellular core CPVC, Radel® (polyphenolsulfone) for the

exhaust vent.

Covering non-metallic vent pipe and fittings with thermal

insulation shall be prohibited.

Location

Recommended Vent Materials

USA

PVC Schedule 40 (solid core)

CPVC Schedule 40 or 80 (solid core)

Approved Polypropylene

Canada*

Type BH Special Gas Vent Class IIA (PVC)

Type BH Special Gas Vent Class IIB (CPVC)

Type BH Special Gas Vent Class IIC (Polypropylene)

Table 12

* For installation in Canada,

fi

eld-supplied plastic vent piping must comply with

CAN/CGA B149.1 (latest edition) and be certi

fi

ed to the Standard For Type BH

Gas Venting Systems, ULC-S636. Components of this listed system must not be

interchanged with other vent systems or unlisted pipes or

fi

ttings. All plastic

components and speci

fi

ed primers and glues of the certi

fi

ed vent system must

be from a single system manufacturer and must not be intermixed with another

system manufacturer’s parts. The supplied vent connector and vent termination are

certi

fi

ed as part of the boiler.

Generally, the boiler limits the flue gas to remain below 150°F (65°C) to

use the flue pipe.

When the return water temperature to the boiler is higher than 140°F

(60°C), DIP switch #1 must be set to ON to release the flue gas limit. CPVC

or PP must be used in such case.

WARNING:

This boiler has a built-in control to limit the exhaust

temperature to 149°F (65°C). As a result, the boiler can be

vented with Schedule 40 PVC.

In high temperature applications, the exhaust temperature

can exceed 149°F (65°C). In that case, to prevent nuisance

tripping of the control you must install Schedule 40

or 80 CPVC or Approved Polypropylene in the USA or

Type BH Special Gas Vent Class IIB (CPVC) or Class IC

(Polypropylene) that conforms to ULC-S636 in Canada.

Then the dip switch setting can be changed to "ON".

In systems with 2 in. vents, if the exhaust temperature

exceeds 149°F (65°C), CPVC pipe (field supplied) must

be used for the first 3 feet of equivalent pipe length. For

systems with 3 in. vents, if the exhaust temperature exceeds

149°F (65°C), CPVC pipe (field supplied) must be used for

the first 5 in. of equivalent pipe length.

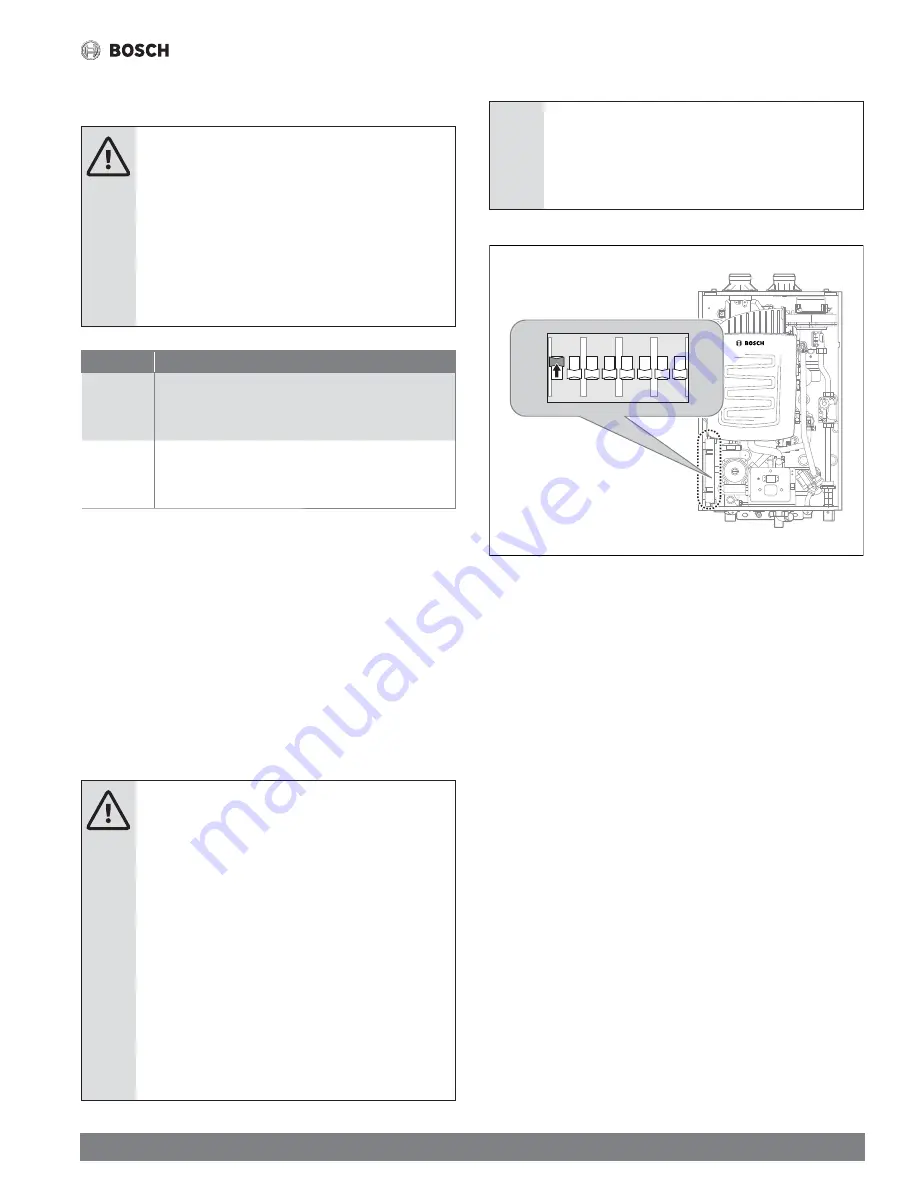

NOTICE:

PCB DIP switch #1 is set to OFF as factory default

When you set PCB DIP switch #1 to ON, ensure that CPVC

piping shall be used for exhaust venting.

Figure 32

1 2 3 4 5 6 7 8

ON