English - 4

Remove the dust cover

17

.

After releasing the SDS lever for

base-plate adjustment

22

and

lightly pushing back the base

plate

7

, it can be tilted left or right to

a maximum of 45°.

The cutting angle can be pre-adjusted by means

of the scale for mitre angles

19

. Precise adjust-

ment with use of a commercial angle gauge

20

is

recommended.

After adjusting the base plate to the 0° or 45° po-

sition, slide the base plate toward the front (direc-

tion of the saw blade) to the stop.

To lock the base plate

7

, shut the SDS lever for

base-plate adjustment

22

.

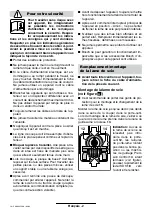

With the thumbwheel for pre-tension of the base

plate

21

, the pre-tension of the SDS lever for

base-plate adjustment

22

can be adjusted. If the

base plate

7

is not seated tightly after shutting the

SDS lever, release the SDS lever

22

and rotate

the thumbwheel for pre-tension of the base

plate

21

in the “

+

” direction.

If the base plate

7

can not be adjusted or only

with difficulty after releasing the SDS lever for

base-plate adjustment

22

, rotate the thumbwheel

for pre-tension of the base plate

21

in the “

–

” di-

rection.

For sawing close to edges, the base plate can be

offset to the rear:

Remove the dust cover

17

.

Release the SDS lever for base-plate adjust-

ment

22

and slide the base plate toward the rear

to the stop.

If the base plate

7

can not be adjusted or only

with difficulty after releasing the SDS lever for

base-plate adjustment

22

, rotate the thumbwheel

for pre-tension of the base plate

21

in the “

–

” di-

rection.

To lock the base plate

7

, shut the SDS lever for

base-plate adjustment

22

. Possibly the thumb-

wheel for pre-tension of the base plate

21

must

be turned toward the “

+

” direction.

– With the base plate offset, only the 0° (normal)

position can be used.

– The circle cutter/parallel guide

24

as well as

the splinter guard

23

cannot be used in this

case.

The aluminium base plate

7

is equipped with a

steel insert for maximum stability. It is intended

for sawing of metal surfaces or insensitive mate-

rials without using the sliding shoe

8

.

When sawing materials that are easily scratched,

the sliding shoe

8

avoids scratching up sensitive

surfaces.

For mounting, insert the sliding shoe at the front

of the foot plate, lift at the rear and latch in.

To avoid fraying of the surface, press the splinter

guard with the notch facing upward

23

(as shown

in the figure) from below into the base plate

7

.

When working with the sliding shoe

8

, insert the

splinter guard

23

into the sliding shoe.

The splinter guard

23

can be inserted into the

base plate in 2 positions. For narrow saw blades,

insert the splinter guard fully to the front; for wider

saw blades, insert it further to the rear in the base

plate.

The splinter guard cannot be used for certain saw

blade types (e. g., saw blades with set teeth).

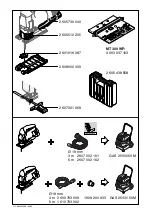

Adjusting the Cutting Angle

(see figure

)

Offsetting the Base Plate

(see figure

)

C

D

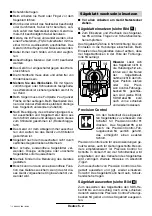

Sliding Shoe for Base Plate

(see figure

)

Splinter Guard (see figure

)

E

E

15 • 2 609 932 280 • 04.03