BOGE Operating instructions for C 15 series screw compressors

Page 25

Installation

3.2

Compressor room

3.2 Compressor room

Installation conditions

for separately arranged

compressed air receivers

Installation surface

A level industrial floor without foundation is adequate for the installation of the

compressor. No special fastening elements are required.

Fire protection

The following applies to rooms in which compressors with oil injection cooling

are to be installed:

Requirements of fire protected compressor rooms:

–

Walls, ceilings, floor and doors must be designed in

fire protection class

F30

or higher.

–

Flammable liquids must never be stored in the compressor room.

–

The floor around the compressor must be made of non-flammable mate-

rial.

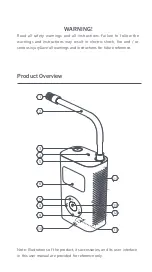

WARNING!

–

Protect compressed air receivers against damage through mechanical

effects (e.g. falling objects).

–

Operate the compressed air receiver and its equipment from a safe loca-

tion.

–

Adhere to safety areas and safety clearances.

–

Ensure that the compressed air receiver stands securely. It must not shift

or tilt due to external forces. This also includes the additional weight dur-

ing a pressure test!

–

The compressed air receiver must

not

be bolted to the base.

–

Ensure that the compressed air receiver is easily accessible from all

sides (for recurring tests). For the necessary operating and maintenance

areas have a look at the attached dimensioned drawings.

–

Ensure that the factory label is clearly visible.

–

Ensure that compressed air receivers are adequatly protected against

corrosion.

–

Only use the compressed air receiver for compressors operating with cut-

in and cut-out mode if the pressure fluctuation range amounts to

Δ

p

≤

20% of the maximum operating pressure.

WARNING!

–

For compressors with motor ratings

exceeding 54 Hp

, ensure that the

compressor room is equipped with special fire protection.

–

Install compressors with motor ratings

exceeding 134 Hp

in a separate

fire protected room.