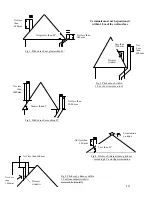

Section 6: Air Supply

Ductwork

All delivery and return air ducts, including air filters, jointing and any insulation

or lining must be constructed entirely of materials, which will not contribute to a

fire, are of adequate strength and dimensionally stable for the maximum internal

and external temperatures to which they are to be exposed during commissioning

and normal operation. In the selection of materials, account must be taken of the

working environment and the air temperatures which will result when the overheat

limit thermostat is being commissioned. Where inter-joint spaces are used as duct

routes, they should be suitably lined with fire-resisting material.

A full and unobstructed return air path to the air heater must be provided.

If the air heater is to be installed in a plant room, the return air and warm air

discharge arrangements must be such as to avoid interference with the operation of

the flue by the air circulation fan. The return air intake and the warm air outlet(s)

should therefore be fully ducted, in the plant room, to and from the heater,

respectively. The openings in the structure of the plant room through which the

ducting passes must be fire stopped.

In addition, where there is a risk of combustible material being placed close to the

warm air outlets, suitable barrier rails should be provided to prevent any

combustible material being within 900mm (3 ft) of the outlets.

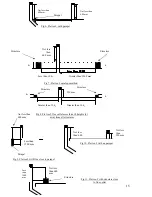

Air flow

It is essential that the correct amount of air is provided through the heater and

should be evenly distributed when entering the heater. All pressure

calculations/resistances for air are ambient with the Heater in the ‘off’ position.

Adjustable by pass plates

BMG models fitted into larger cabinets for internal or external use should be fitted

with adjustable air balancing plates or a simple restriction damper. If the work is

not going to be carried out by BMM Heaters Ltd then we recommend that the

installer ensures that it can be altered to give guaranteed minimum equal air over

the combustion chamber/heat exchanger (see minimum and maximum air flow

volumes in section 4 table 1).

9