3

INSTALLATION

Installation Instructions

GENERAL

The SN-3E and SN-5E steamers are single compartment

electric pressureless steam cookers with

an internal electric steam generator that maintains water

temperature at approximately 205EF.

SN-3E is rated 7.5 kW as standard; 10 kW is optional.

SN-5E is rated 12 kW as standard; 15 kW

is optional.

At high altitude locations a lower temperature is required

to achieve atmospheric steaming.

Contact your authorized service office to have the ther

-

mostat adjusted if the steamer will be

operated at high altitudes.

UNPACKAKING

Immediately after unpacking the steamer, check for pos-

sible shipping damage. If the steamer is found to be dam-

aged, save the packaging material and contact the carrier

within 15 days of delivery.

Prior to installation, verify that the electrical service agrees

with the specifications on the machine data plate which is

located on the left side panel.

LOCATION

Allow space for plumbing and electrical connections.

Allow adequate access for operating and servicing the

steamer (36” at the front of the steamer and 15” above

the steamer).

LEGS (OPTIONAL)

If the optional 4” adjustable legs are used, remove the

four levelling feet on the bottom of the steamer.

FEET

Levelling Feet (standard) or 4” Adjustable Legs (Op-

tional)

Thread the four 2” levelling feet shipped in a bag inside

the steamer cabinet into the threaded holes on the bot-

tom corners of the steamer. Or, thread the four optional

4” adjustable legs into the threaded holes on the bottom

corners of the steamer.

LEVELLING

Using a spirit level or pan of water in the bottom of the

steamer, adjust the levelling feet or the feet on the ad-

justable legs to level the steamer front-to-back and side-

to-side. After the drain is connected, check for level by

pouring water onto the floor of the compartment. All water

should drain through the opening at the back of the com-

partment cavity.

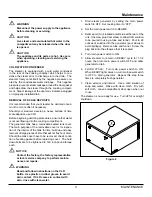

ANCORING STEAMER (WITHOUT LEGS)

1. Place steamer in the desired location on the lev-

elled counter top and mark four corners. Remove the

steamer and drill ½” holes as indicated in Figure 1.

2. Apply a bead of RTV or other equivalent sealant

around bottom perimeter edge of the steamer. If an-

choring the steamer, this bottom seal is necessary to

meet NSF requirements.

3. Set steamer on counter and bolt down securely with

3/8 - 16 bolts (not supplied).

STACKING KIT

Follow instructions in the stacking kit when installing

stacked convection steamers.

Figure 2