INSTALLATION

CB9A-030 page 9/28

RELIEF VALVES

A relief valve of a type, material and pressure rating

suitable to the installation, MUST be installed. The

relief valve shall be installed in the discharge line

between the compressor head and the first block valve.

Hazardous pressure

can cause serious

personal injury or

property damage

Compressor operating against closed

valve can cause system component

failure, personal injury or property

damage.

Since all systems differ in design, care must be taken to

ensure the relief valve is installed to safely vent away

from sources of ignition and personnel. This can be

accomplished by either orientation or a pipe away,

consult the Relief Valve manufacture for assistance.

Should the Relief Valve actuate, the cause MUST be

determined and corrected before continuing operations.

See the 'Troubleshooting' section.

Hazardous gases

can cause property

damage, personal

injury or death

Operation of the relief valve can release

explosive gas to the atmosphere

creating an explosion hazard, possibly

causing personal injury or death

Blackmer offers various relief valves for gas and

application compatibility.

PRESSURE GAUGES

Install pressure gauges in the discharge and inlet lines

to verify actual suction and discharge pressures.

LIQUID TRAPS

Compressors handling gasses that contain

condensates or other liquids MUST be protected from

entry of the liquid. Liquid can also enter the compressor

from the discharge piping, particularly if the piping

slopes down toward the compressor. To prevent liquid

from entering the compressor and causing major

damage, it is necessary to carefully consider the system

design and have strict procedures for operation.

NOTICE: Liquid in the compressor cylinder can

cause destruction of the compressor.

Suction liquid traps collect liquid entrained in the suction

gas stream, preventing it from entering the compressor.

The most common liquid trap is an ASME code vessel

(approx. 12" diameter X 50" tall) fitted with an internal

stainless steel mist pad, a relief valve, a manual drain

valve, and one or two electric float switches. Level

gauges and automatic drain systems are also available.

If the liquid level rises too high in the trap, a float switch

is tripped, sending a signal to stop the compressor or

sound an alarm. The trap must then be drained before

the compressor can be restarted. The cause of the high

liquid level must be found and the problem corrected.

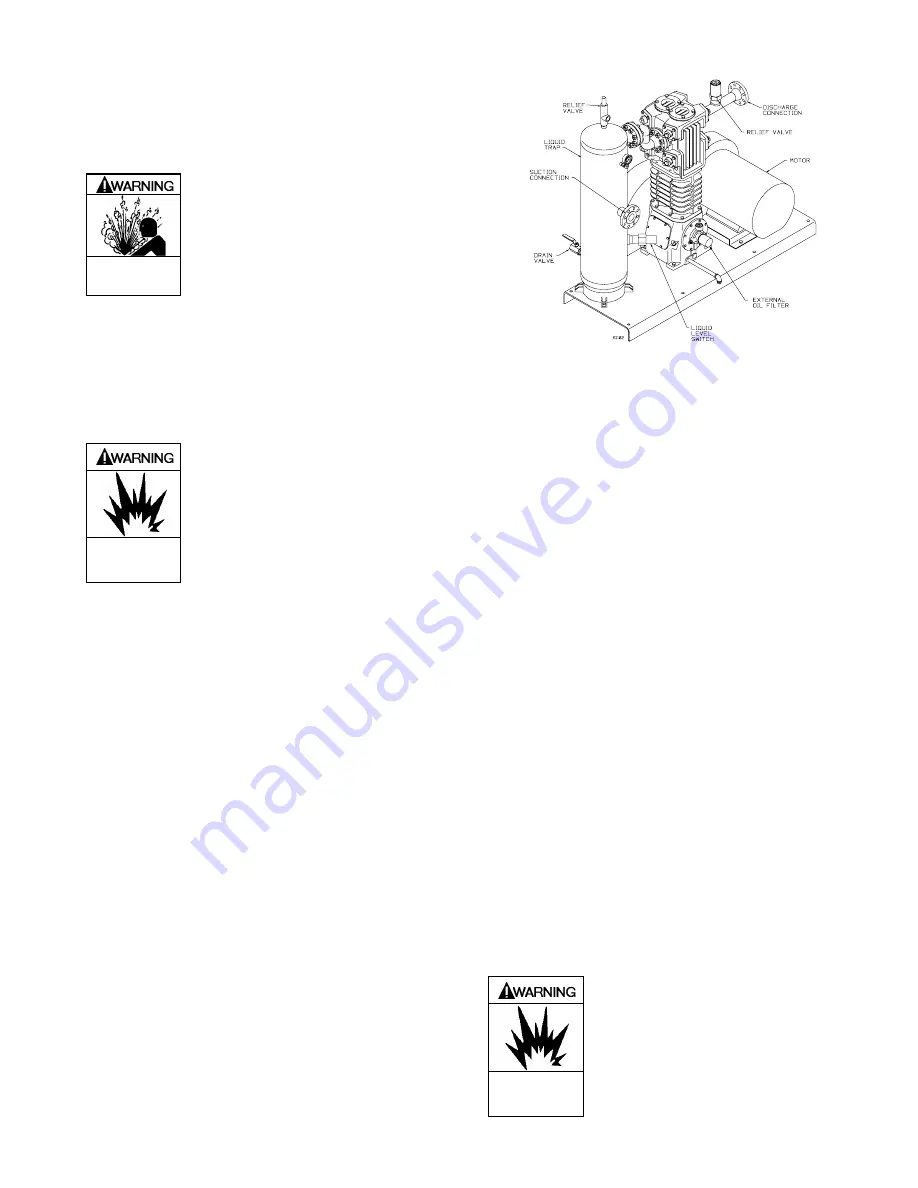

Figure 5 – Typical HD942 Compressor Package

4-WAY VALVES

Many liquefied gas compressors are used for both liquid

transfer and vapor recovery operations. An optional 4-

way valve is used to reverse the direction of flow

through the system when changing from liquid transfer

to vapor recovery. Both lubricated and nonlubricated

models are available. Lubricated models should be

lubricated every 6 months.

TEMPERATURE SWITCHES

Excessive discharge temperature is a leading cause of

premature component failure and is often an early

warning sign of impending problems.

Optional temperature switches should be installed with

a thermowell as close to the compressor discharge as

possible. The switch should be set to actuate at a

temperature just above the maximum operating

temperature of the compressor.

ATEX compliant compressors

must

have a temperature

switch installed.

LOW OIL PRESSURE SWITCHES

Loss of crankcase oil pressure is a rare occurrence, but

can result in costly damage. An optional low oil

pressure switch set at about 15 psig (1 bar-g) may be

installed to shut down the compressor in the event of a

lubrication failure. A 10 second delay timer should be

used to lock the low oil pressure switch out during

compressor startup.

PRESSURE SWITCHES

Pressure switches may be installed in the suction or

discharge gas stream as protective devices, for

compressor control, or for other uses varying with each

application and system design.

Hazardous gases

can cause property

damage, personal

injury or death

Optional liquid trap level switches,

temperature switches, pressure

switches or other electrical devices

must be properly specified for

applications using explosive gases.

Summary of Contents for HD942A

Page 26: ...NOTES CB9A 030 page 26 28...

Page 28: ...1528 3 e 5...