(5)

Turn Gas Cock Dial to “ON” position (only for USA and Canada).

(6)

Turn the thermostat knob. The indicator light near the thermostat will illuminate and the burners

will come on.

(7)

Turn the Timer Knob and set a time of 2 minutes. At the end of 2 minutes, you should hear the

buzzer. Turn the timer knob to “0”, to stop the buzzer.

(8)

Open the oven doors. Oven lights will go on and burners and fan will go off.

(9)

Turn Selector Switch to “Cool Down” position. The fan will run to cool down the oven.

(10)

Turn Selector Switch to “0” position.

(11)

Close the oven doors.

NOTE: OVEN STARTS HEATING AS SOON AS THE SET TEMPERATURE IS HIGHER THAN THE

OVEN TEMPERATURE WITH THE OVEN DOORS CLOSED AND THE SELECTOR SWITCH NOT IN “0”

POSITION.

THERMOSTAT INDICATOR LIGHT GOES OUT WHEN OVEN REACHES SET TEMPERATURE AND

COMES ON WHEN OVEN IS HEATING UP.

IN THE EVENT OF POWER FAILURE, THE OVEN WILL NOT OPERATE. RESTORATION OF POWER

AFTER ANY DURATION, WILL RETURN UNIT TO NORMAL OPERATION.

J. PROGRAMMING MENUS (for units with digital controls):

Refer to C&H - 3 Plus Controller Operating/Programming Instructions Manual.

II. OPERATING INSTRUCTIONS

A. GENERAL INSTRUCTIONS:

(1)

This equipment has an Electronic Temperature Control and Electronic Hot Surface Direct

Ignition System.

(2)

Due to increased efficiency of this oven, the temperature of standard recipes may be reduced

50°F (30°C).

(3)

Always load each shelf evenly. Space pans away from each other and from sides and back of

oven to allow maximum air flow between them.

(4)

Large tempered glass windows and interior lights allow a close check on the product, making it

unnecessary to frequently open the doors. Products cook faster in a convection oven as

compared to a conventional oven. Depending on the product and the type of pans used, time

saving may run from 20 percent to as high as 50 percent.

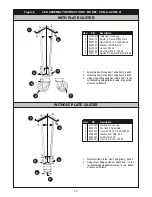

B. OPERATION SEQUENCE ROTARY CONTROL:

Cook only rotary control:

(1)

Close the oven doors.

(2)

Turn Selector Switch to “HI” or “LO” position. The indicator light near the Selector Switch will be

illuminated.

(3)

Turn the thermostat knob to the desired cooking temperature.

(4)

Upon reaching the set temperature, the indicator light near the thermostat will go out.

(5)

Load the oven with product to be cooked.

(6)

Remove the product from the oven when done.

Timed cooking rotary control:

(1)

Close the oven doors.

(2)

Turn Selector Switch to “HI” or “LO” position. The indicator light near the Selector Switch will be

illuminated.

(3)

Turn the thermostat knob to the desired cooking temperature.

(4)

Upon reaching the set temperature, the indicator light near the thermostat will go out.

(5)

Load the oven with product to be cooked.

(6)

Turn the timer knob to the desired bake time and timer will start counting down.

6