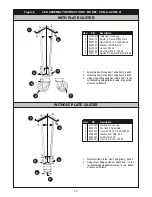

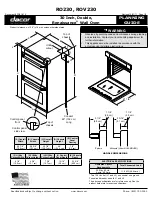

D. LOCATION AND MINIMUM CLEARANCES:

Move the oven to its final location keeping the minimum clearance from the back of the oven to the wall. This

clearance is necessary for safe operation and to provide proper air flow to the burner chamber.

MINIMUM CLEARANCES FROM COMBUSTIBLE AND NONCOMBUSTIBLE CONSTRUCTION

Under Ventilation Hood

Direct Venting

RIGHT WALL

1”

1”

LEFT WALL

1”

3”

REAR WALL

3”

3”

E. GAS CONNECTION:

The ovens should not be installed on the same gas supply line with space heaters, boilers or other gas

equipment with high intermittent demand.

The installation of the oven must conform to the latest local codes or

National Fuel Gas Code, ANSI Z223.1,

Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Installation Code, CAN/CGA-B149.2.

The appliance must be isolated from the gas supply piping system by closing its manual shut-off valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than ½ psig

(3.45kpa). The appliance and its shut-off valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of ½ psig (3.45kpa).

Use a pipe joint compound that is resistant to the action of liquefied petroleum gases when making gas

connections. For Propane gas, use at least ½” (13 mm) pipe or tubing with a 5/8” (16 mm) inside diameter.

For Natural gas, use ¾” (19 mm) pipe.

The gas pressure regulator is part of the combination valve and is adjusted to yield a pressure of 3.5” water

column (9 mbar) for Natural Gas. If the oven is ordered for use on Propane Gas or Butane, the pressure

regulator in the combination valve is preset at the factory to yield a pressure of 10” water column (25 mbar).

NOTE:

No external regulator is required.

Gas supply pressure in the European Community countries should be as below.

Gas Type Supply Pressure

Gas Type Supply Pressure

G20

20 mbar

G30

30 or 50 mbar depending on country

G25

25 mbar

G31

30, 37, or 50 mbar depending on country

G20/25

20/25 mbar

A separate shut-off valve for each oven must be provided. It should be as close as possible to the place

where the gas line goes into the oven. It must be located such that it is easily accessible. When stacking with

another oven, two shut-off valves, one for each of the two ovens, must be provided.

After the Gas Supply has been connected, it is extremely important to check all the piping for leaks.

Use a soap and water solution or a product expressly made for this purpose. Do not use matches,

candles or a flame and so forth to check leaks since these methods are extremely dangerous.

4

CAUTION:

Do not set the oven with its back flat against the wall. It will not operate

properly unless there is at least three inches breathing space behind the oven

!

!

Suitable for installation on combustible floor when installed with legs or casters

provided.

!

!

CAUTION:

Do not store combustible items or materials on racks.

!

!