F. ELECTRICAL CONNECTION:

The oven, when installed, must be electrically grounded in accordance with local codes and/or the latest

edition of the National Electrical Code ANSI/NFPA No. 70 in the USA (Canadian Electrical Code CSA

Standard C22.1, Part 1 in Canada).

In Europe, the appliance must be connected by an earthen cable to all other units in the complete

installation and, thence, to an independent earth connection in compliance with EN 60335-1 and/or local

codes.

The electric motor, all the related switches, interior lights, and the timer/buzzer are all connected through

the 6-foot (1829 mm) power supply cord located at the rear of the oven. The supply cord must be plugged

into a properly grounded, three-prong receptacle. DO NOT CUT OR REMOVE THE GROUNDING PRONG

FROM THE PLUG.

Normal factory connections are made for 120 volts A.C., 60 hz, Service in USA and Canada or 240 volts

A.C., 50 hz service in European community countries. Other voltages can be supplied upon request.

Electrical characteristics of this unit can be found on the rating plate located on the right side of the unit.

This unit is provided with a permanently lubricated electric motor. A wiring diagram may be found on the

back of the service panel on the right-hand side and in this manual.

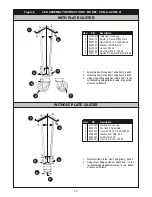

G. FLUE CONNECTION VENTILATION:

Installation under ventilation hood (standard):

If the oven is not vented directly and is installed under a ventilation hood, the unit is ready to be installed as

is. Local inspectors and ventilation specialists should be consulted so that the design and the installation of

the hood conform to local/municipal codes. In the U.K., follow ventilation requirements as detailed in B.S.

5440.

Optional direct venting (not available for European community countries):

If direct venting, a flue adapter and a draft hood are required to be installed. They prevent the flue gases

leaving the oven to be affected by the air pressure changes on the outside of the flue stack extending out of

the building.

The flue pipe from the draft hood must not run downwards at any point from the oven to the final

outlet. It should always slant slightly upwards. For best results, is should rise straight up. The venting

system shall be in accordance with the National Fuel Gas Code, ANSI Z223.1 / NFPA 54 and or the CSA

B149.1, Natural Gas and CSA

B149.2, Propane Installation Codes, and local codes.

NOTE: DO NOT PUT A DAMPER IN THE FLUE AND DO NOT CONNECT A BLOWER DIRECTLY TO

THE FLUE.

If the flue runs directly to the free air outside the building, use a wind deflector or a UL listed vent cap at the

end of the pipe. Termination of the vent must be at least two feet above the highest part of the roof within ten

feet. REF: AGA CATALOG NO. XH0474.

H. BURNER OPERATION:

The oven burner flame should always have a blue appearance. This indicates a good mixture of air and gas.

When using LP gas, the flame will have a blue-yellow appearance. There may be intermittent yellow-orange

flame noticed. This is caused by dust particles burning in the flame.

I. SYSTEM CHECK- ROTARY CONTROL:

(1)

Open the oven door.

(2)

Turn Selector Switch to “HI.” The indicator light near Selector Switch and oven light will

illuminate.

(3)

Close the door. Oven lights will go off and fan will run. Make sure fan is rotating clockwise looking

from front.

(4)

Press Oven Light switch. Oven light will go on and will go off when switch is released.

5