KT-420-4 // PDF Download

46

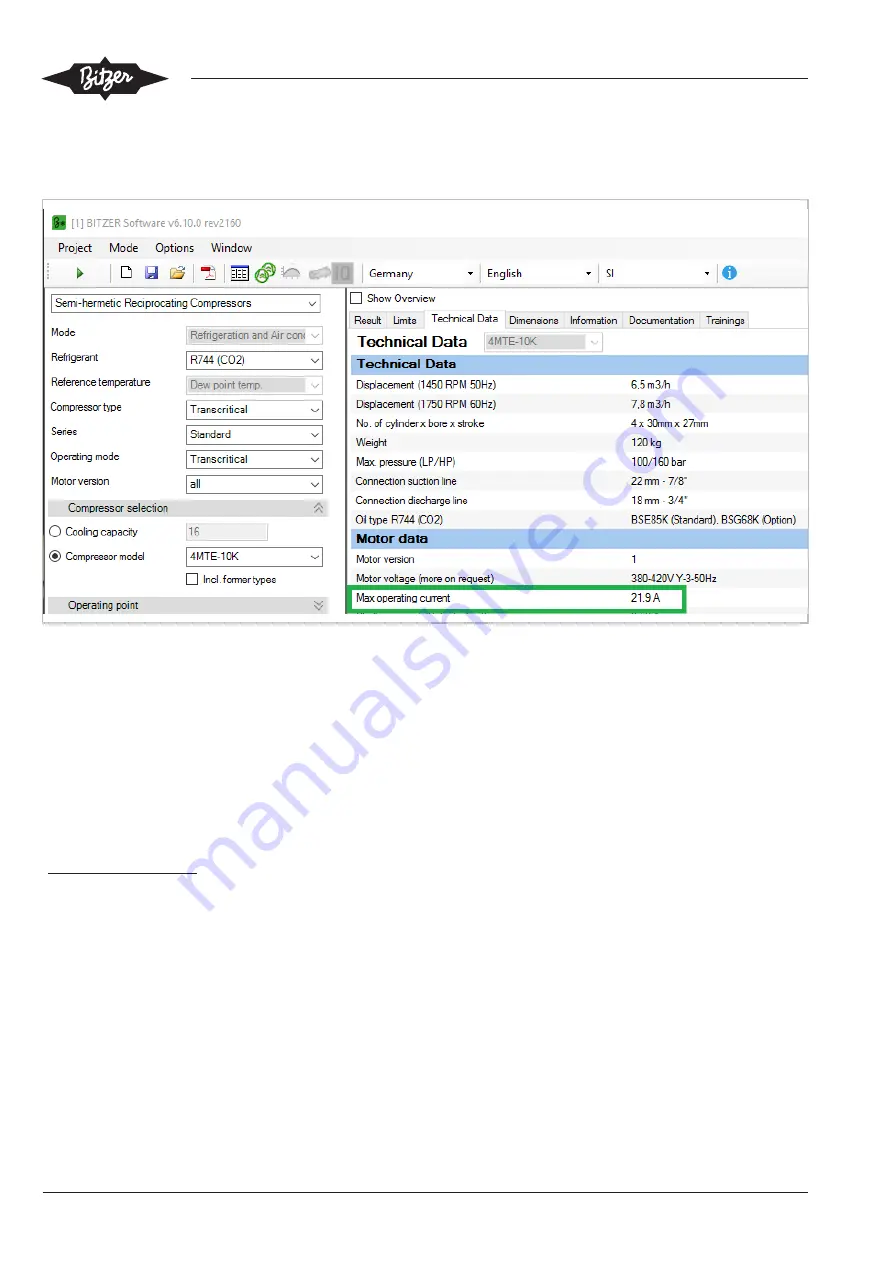

This factor is multiplied by the "Max. operating current" that the BITZER SOFTWARE indicates for the respective

motor in the tab "Technical data" (see figure below). This maximum current must be within the short-term overload

capacity of the frequency inverter, otherwise a larger frequency inverter is necessary.

Fig. 10: The "Max. operating current" indicated in the BITZER SOFTWARE (here: 21.9 A)

multiplied by the compressor-specific compensation factor (for 4 cylinder compressors: F = 1.6)

gives the necessary short-term overload capacity of the frequency inverter.

For BITZER VARIPACK frequency inverters, this is already taken into account by design.

4.2

Compressor motors

The frequency inverter cannot deliver voltage above the supply voltage. Therefore, the stator voltage cannot in-

crease any further with higher inverter frequency. The magnetising current in the main inductance drops, the stator

rotating field and torque are weakened.

This means that when raising the frequency above the synchronous speed, the voltage-frequency ratio U/f falls.

Since the torque required by the compressor remains constant, the current consumption of the motor will increase

(

). Therefore, the motor should have adequate reserve (current / power) at supply fre-

quency. The frequency / speed can be increased up to the maximum motor current (RMS – root mean square) (see

maximum operating current on the name plate or in the BITZER SOFTWARE).