MAINTENANCE

SHARP MOVING BAND TYPE SAW BLADE

TO AVOID SERIOUS PERSONAL INJURY

ALWAYS

Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine

BEFORE

Removing Shrouds, Removable Guards, Covers, Doors, Fences or Panels

for Cleaning, Servicing or Any Other Reason.

ALWAYS

Read Operating and Service Manual

BEFORE

Operating, Servicing or Cleaning.

NEVER

Touch This Machine Without Training and Authorization By Your Supervisor.

NEVER

Bypass, Alter or Modify This Machine in any Way From its Original Form. This

Machine in its Original Form Meets the Intent of O.S.H.A. Applicable Standards.

ALWAYS

Keep Hands Clear of Band Type Saw Blade and Other Moving Parts.

PROMPTLY REPLACE

Any Worn or Illegible Labels.

USE ONLY GENUINE BIRO

Parts and Accessories Properly Installed.

A. GENERAL

1. Machine should be generally inspected every time it is cleaned (at least daily) to ensure that it is in good

condition and has not been damaged or tampered with.

a.

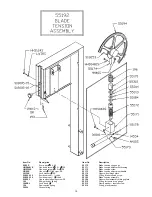

SAW WHEELS:

Clean outer diameter grooves daily. Check for cracks, gouges or wear on flange and

grooves.

DO NOT IMMERSE UPPER WHEEL ASSEMBLY IN WATER

b.

WHEEL CLEANER ASSEMBLIES:

Check condition of fiber cleaner, change every four (4) weeks.

c.

REMOVABLE FINGER LIFT ASSEMBLY:

Check condition of saw guard, make sure mounting bolts are

tight and “DANGER EXPOSED BLADE” decal is attached and legible. Check condition of upper saw

guide (Part No. 602B), replace every six (6) months. Check adjustment of upper saw guide. Should be

1

32

" between back of blade and saw guide carbide.

d.

SAW GUIDE BAR:

Check condition of inner and outer saw guide bar, replace as necessary. Check saw

guide bar spring for proper tension. The spring should hold the bars in any desired position in its travel.

Replace saw guide bar spring (Part No. 193) as necessary using instructions on following page.

9

NEVER USE THIS MACHINE WITHOUT PROPERLY INSTALLED

AND FUNCTIONING SAW GUIDE BAR WITH SAW GUARD

Summary of Contents for 55

Page 5: ...3 ...

Page 7: ...WARNING LABELS FOR BIRO POWER SAWS SEE PAGE 11 FOR LOCATIONS ON MACHINE 5 ...

Page 14: ......

Page 15: ...13 ...

Page 19: ... NOTES 17 ...

Page 21: ......

Page 26: ...Wing nut 7 16 14 SS ...

Page 27: ......