Biodom 33

Biodom 33

Biodom 33

Biodom 33

|

|

|

| instructions for use, maintenance and installation |

version 1.0 July 2017

48

-

the expansion (expansion) tank volume of 18 liters which is sufficient for the system of

central heating, which contains up to 200 liters of heating water in the system (boiler

contains 142 liters of heating water). In the case where the system is more than 58 liters of

the heating water the installer must ensure a further expansion tank for the quantity of

heating water in the system over 200 liters (the size of the expansion tank must be sized to a

minimum of 9% of the amount of water in the system "300 liters of water in the heating

system, , the minimum size of the additional expansion tank must be 9 liters "). The

expansion tank must be installed on the boiler Biodom 33 without locking elements

.

•

safety valve of 2.5 bar on return line.

•

A filling release tap must be installed on the right side of the boiler, on connection DN20.

•

Minimal pressure of heating water in boiler of 0.7 bar is ensured.

•

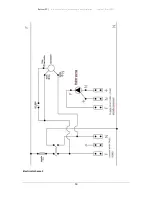

In case where there are many heating loops (two direct loops or mix loops for radiator heat-

ing, boiler heating, convector heating),

connection scheme nr. 3

is always used, where it is

necessary to use a hydraulic switch.

•

Boiler must be fitted with pressure gauge for pressure of heating water in the boiler, i.e. on

pipeline before each closing valve (enable that the pressure gauge indicates pressure in the

boiler and system; in the time of filling "there cannot be a closing element, which could pre-

vent indication of pressure in the boiler in the time of filling"). On the right side of Biodom 33

is a provided DN15 connection for filling release tap. Filling release tap is intended for filling

or emptying the heating system and boiler.

•

When connecting the boiler Biodom 33 to central heating system you must use mechanical

elements, which prevent uncontrolled circulation of hot heating water through the boiler

(gravity block, spring non-return valve, solenoid zone valve, electromotor zone valve...). goal

of protection is to ensure amount of heating water flow through the boiler (minimal flow

through the boiler must be over 300 l/h).

•

When distribution of heating water is regulated by three-way mix valve (floor heating,

weather controlled regulation, where water flow on boiler heating loop is reduced), the sys-

tem is executed with fitted hydraulic switch.

•

When a three-way mix valve is used (for floor or radiator heating, only in case of only one

mixing heating loop), connection of boiler Biodom 33 is always executed according to

scheme

nr. 3

, where a hydraulic switch is built into the installation on heating cycle.

•

Flue connection must executed in accordance with instruction limiting maximum length of

connection pipe Ø 80 (5 m) and that 90-degree joints are considered as resistance on connec-

tion, which reduces length of connection pipe for 1 m (example: if there are 2 joints on flue

connection, the connection cannot exceed length of 3 m). Flue connection must be fitted

with joints with inspections holes for cleaning (see

figure 3

, page 11

). Joints must be out of at

least 3 segments (joints with three or more segments enable smooth flow of smoke gases

through joint), it is prohibited to use joints with two segments (joints with two segments cre-

ates resistance in flow of smoke gases) (see

figure 6

, page 12

).

•

If the flue connection is longer as set forth in the instructions, the installer must use a reduc-

ing element (from Ø 80 female connection to Ø 130 female connection) immediately behind

the fan, and the connection must be made with a pipe Ø 130.