GWR-2000 Four-wire 4-20 mA/HART

925-0335 Rev B

9 Diagnosis, asset management and service

52

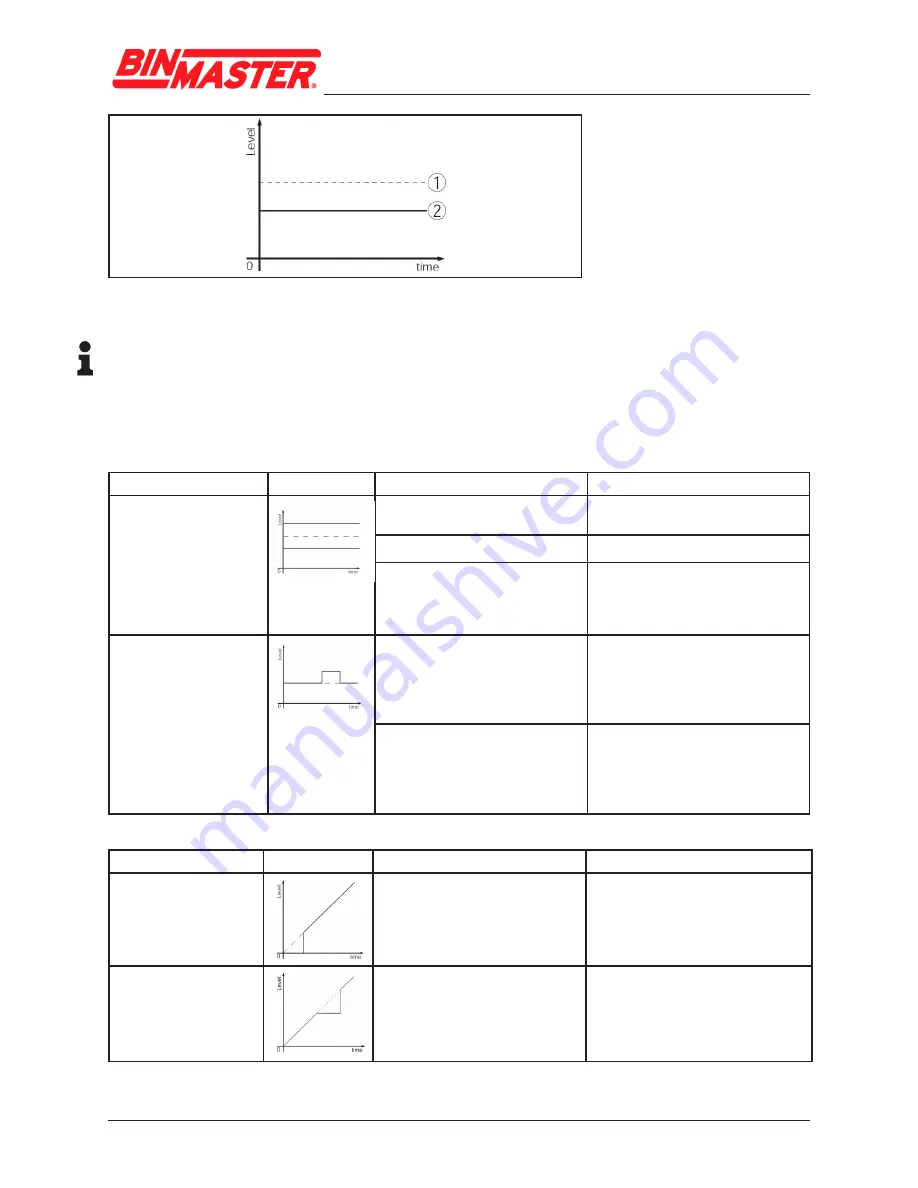

1 Real level

2 Level displayed by the sensor

Note:

●

Whenever the sensor displays a constant value, the reason could also be that the fault set-

ting of the current output is set to "Hold value"

●

If the level indication is too low, the reason could be a line resistance that is too high

Measurement error with constant level

Fault description

Error pattern Cause

Rectification

1. Measured value

shows a too low or

too high level

- Min./max. adjustment not

correct

- Adapt min./max. adjustment

- Incorrect linearization curve

- Adapt linearization curve

- Running time error (small

measurement error close to

100 %/serious error close

to 0 %)

- Repeat setup

2. Measured value

jumps towards 100 %

- Due to the process, the am-

plitude of the product echo

decreases

- A false signal suppression

was not carried out

- Carry out a false signal sup-

pression

- Amplitude or position of a

false signal has changed

(e.g. buildup); false sig-

nal suppression no longer

matches

- Determine the reason for the

changed false signals, carry

out false signal suppression,

e.g. with buildup

Measurement error during filling

Fault description

Error pattern Cause

Rectification

3. Measured value

remains in the area

of the bottom during

filling

- Echo from the probe end

larger than the product

echo, for example, with

products with εr < 2.5 oil-

based, solvents, etc.

- Check parameter "Medium"

and "Vessel height", adapt if

necessary

4. Measured value

remains momentarily

unchanged during

filling and then jumps

to the correct level

- Turbulence on the product

surface, quick filling

- Check parameters, change if

necessary, e.g. in dosing ves-

sel, reactor