- 39 -

INST

A

ll

ATI

o

N

INSTAllATIoN

6.5 Joints

Functions

Pipe sizes

(o.d)

Gas, c.h. return, c.h. flow

ø 22

D.c.w. inlet

ø 15

D.h.w. outlet

ø 15

Pressure relief valve

ø 15

Condensate drain

ø 25 (plastic)

sizes in mm o.d.

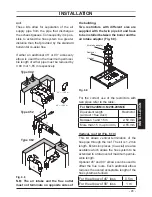

6.6 Mounting the boiler

• Take the protective caps off the boiler

pipework.

• Thoroughly clean the connections.

• Mount the boiler on its bracket.

• Fix the c.h. valves A and gas cock B (¾”) to

the boiler using the ¾” gaskets (Fig. 6.3).

• Fix the ø 22 mm pipes C (c.h. circuit) to the

c.h. valves A and the ø 22 mm pipe D (gas)

to the cock B using the ¾” gaskets.

• Repeat the above procedure for the d.c.w.

inlet utilising the ½” cold water inlet valve

J, the ø 15 mm copper tail E with its con-

nection nut and two ½” gaskets.

• Fix the ø 15 mm copper tail F with the ½”

connection nut and a ½” gasket.

Fig. 6.3

A

A

b

C

C

D

J

E

F

• Connect the pipe G (Fig. 6.4) from the

pressure relief valve to the safety dis-

charge pipework.

• Fit the condensate drain 11 (Fig. 6.4) in the

air brake connected to the drainage pipe-

work. See also section "Condensate drain"

to page 33.

Fig. 6.4

G

11

6.7 Fitting the flue system

Refer to the assembly instructions contained

within the chosen flue kit packaging for the

correct assembly and installation.

In general, it has to be taken in considera-

tion that the horizontal sections of the flue

pipe must have an horizontal sloping not

less than 1.5 deg. (25 mm per metre) to-

wards the boiler.

In the standard horizontal flue kit the flue

pipe is angled within the air duct therefore

the air duct must be horizontally installed.

Fig. 6.5

If one or more extensions have to be used

they must be adequately supported so that

Summary of Contents for Riva Plus HE M296.24SC

Page 56: ...56 NOTES...

Page 57: ...57 NOTES...