12

Should the circuit breaker trip repeatedly then the most

probable causes are:

-Abnormal working conditions,

-Treadmill belt in need of lubricant,

-Solvent based lubricants used (use BH type),

- Belt is too tight.

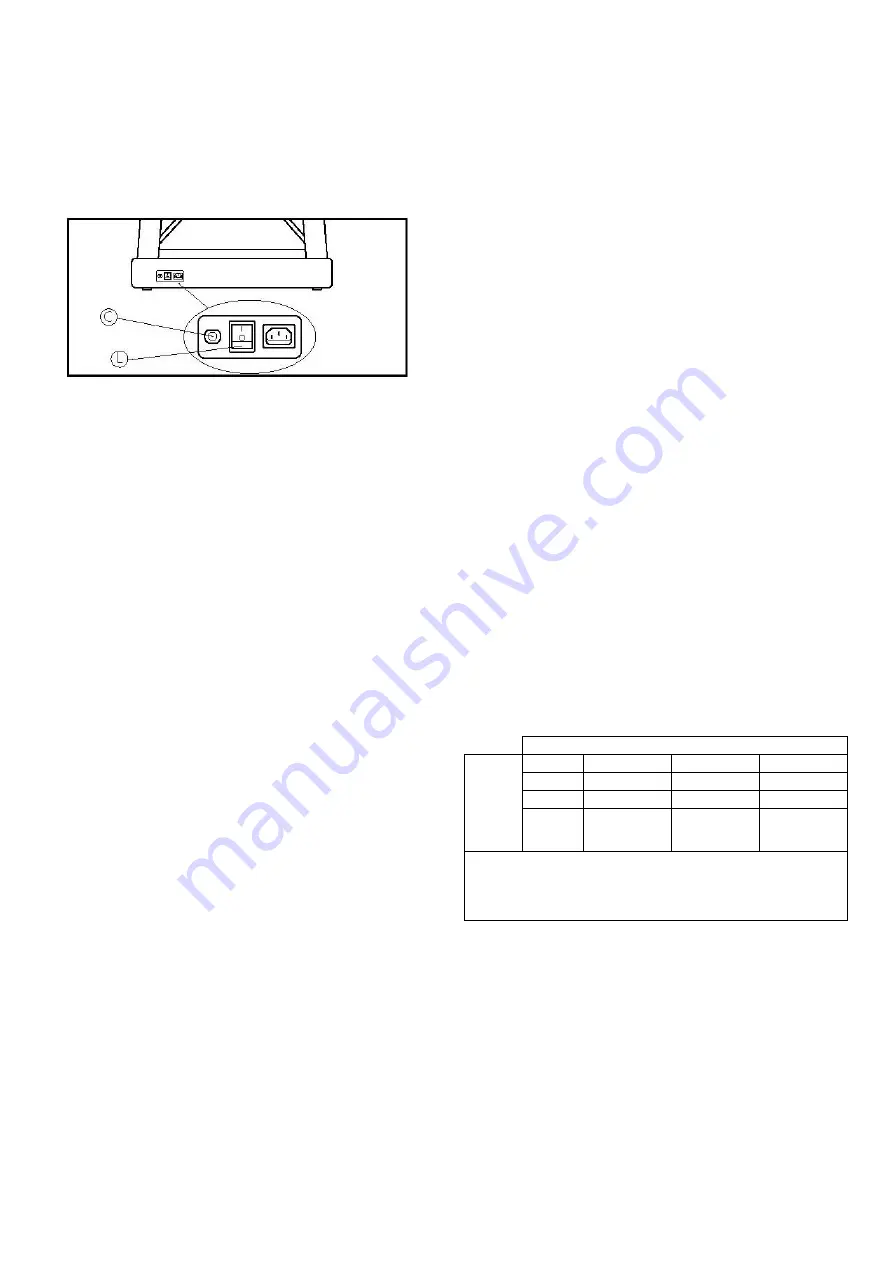

Plug the unit into a wall socket with an EARTH terminal.

Set switch (L) to Position [1].

Fig.B

ASSEMBLY INSTRUCTIONS.-

Take the unit out of the box and place it on the floor as

shown in Fig.0.

The assistance of a second person is advisable for

the assembly work.

Make sure that all of the pieces are there:

(1) Main structure.

(80) Side bar (left).

(81) Side bar (right).

(84) Tray.

(85) Monitor support.

(8) Internet cable fix plate.

(200) Monitor.

(156) Bottle of lubricant.

(121) Screw M8x20.

(122) Screw M8x15.

(123) Screw M8x50.

(55) Screw M4x10.

(124) Cap.

Wrenches.

Follow the instructions step by step to assemble:

1. FITTING THE SIDE BARS.-

At least two people are needed to assemble the machine

.

This will avoid any possible accidents.

Place the left side bar (80), Fig.1, close to the main

structure and get the wires (TV, internet) through the left

side bar (80). Then slightly screw the left side bar (80) to

the structure using the screws (122), (123). Fit the caps

(124).

Then place the right side bar (81), Fig.1, close to the main

structure and get the power cable, the monitor cable and

the ground cable through the right side bar (81). Then

slightly screw the right side bar (81) to the structure using

the screws (122), (123). Fit the caps (124).

2. ATTACHING THE MONITOR TUBE.-

Take hold of the handrail (84) and connect the cables with

wires sticking up out of the handlebars.

Once this is done, rest the handrail handlebar on top of

the focus bars, making sure not to catch any of the cables.

Now tighten using the screws (121), Fig.2.

Tighten the screws of the side bars of the previous steps.

Attach the fixing support (8) onto the structure using the

screws (55), Fig.3.

3. ATTACHING THE MONITOR.-

Place the monitor support (85) on the tray (84), fix it with

the screws (122) and fasten securely, Fig.4.

Remove the screws from back cover of the monitor and

remove the back cover, Fig.5.

Connect the wires coming out of the monitor with the wires

coming out of the tray. Remove the screws from the back

part of the monitor. Place the monitor on the support and

fix it with the previously removed screws.

Next fix the rear cover using the previously removed

screws, making sure that the wires are not pressed, Fig.6.

MOVEMENT & STORAGE.-

The unit is equipped with wheels (71), Fig.7 to make it

easier to move. Make sure that the mains cable is

unplugged from the wall socket.

To prevent accidents DO NOT move the treadmill across

uneven floors.

MAINTENANCE.-

Use the bottle of lubricant (156) to lubricate the inside of

the belt Fig.8 in order to keep your unit in top condition

and to ensure that friction between the belt and the board

is kept to a minimum (due to different running styles,

always apply more lubrication to the area where you place

your feet during the exercise).

It is advisable to lubricate the base of the belt between the

board and the band depending on how often it is used.

Hours per week

S

pe

ed

(

k

m/h

)

<3

3-7

>7

<6

1 year

6 months

3 months

6-12

6 months

3 months

2 months

>12

3 months

2 months

1 month

Note: This preventive maintenance schedule is only

meant for home use.

It is suggested to maintain the unit every month for

commercial use.

If the belt starts to slip after lubrication, then check the

tension of the belt. To tension the belt, take the 6mm Allen

key and with the machine set to 4km/h turn screws (R & L)

one turn in a clockwise direction.

ADJUSTING THE BELT.-

If your unit is not seated evenly on the four contact points,

this may cause the belt (X) to shift sideways. Rigorous

quality control adjusts and checks the running belt.

However, due to weight differences and individual styles

of running, the belt may be prone to shift sideways. If the

belt does shift to the left or right, stop the machine.

Summary of Contents for 3265707

Page 2: ...2 Fig 0 ...

Page 3: ...3 Fig 1 Fig 2 ...

Page 4: ...4 Fig 3 Fig 4 ...

Page 5: ...5 Fig 5 Fig 6 Fig 7 Fig 8 Fig 9 ...

Page 41: ...G688BM ...