26

Bentone BG550/650

General

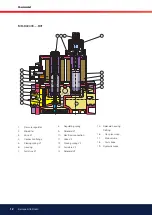

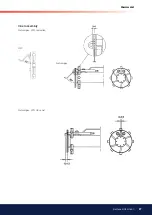

Multibloc

Gas train

5. Measures and checks

before start-up

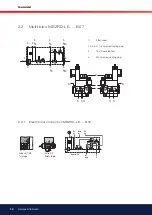

5.1

2-Stage or modulating burners

General rules

Care should be taken by the installer to ensure that

no electrical cables or fuel/gas pipes are trapped or

damaged during installation or service/maintenance.

Inner assembly

Ensure that the ignition and ionisation electrodes are

correctly adjusted. The sketch (see separate page)

shows the correct measurements.

Gas quality

Ensure that the burner head is meant for the gas quality

to be used (see ig.).

Venting

The gas line is vented by loosening the screw on the test

nipple for the inlet pressure. Connect a plastic hose and

conduct the gas into the open air,

After having vented

the gas line tighten the screw again.

Leakage control

When making a leakage control of the gas supply

system, the solenoid valve should be closed. Connect

a pressure gauge to the test nipple Pa, see ig. The

test pressure in the system should be 1,5x max. inlet

pressure or min. 150 mbar. If any leakage, locate the

source by means of soapy water or a leak location spray.

After tightening repeat the test.

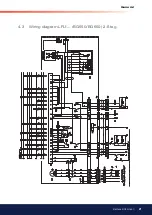

Electric function test:

Ensure that phase and neutral are not reversed. The

gas shut-off cock should be closed.To prevent the gas

pressure switch from locking out, it should be linked

temporarily.

After the main switch has been switched on and the

thermostats have been adjusted, the pre-purging period

begins (30-35sec.). At the end of this period the pre-

ignition period starts (0,5-2,5 sec. depending on the

design of the gas control). The gas valve is energized

and opens and lame is established. At the end of the

safety time (2-3 sec.) the gas control locks out. The

solenoid valve and the motor will be ”dead”. Remove

the link from the gas pressure switch after the test is

inished.

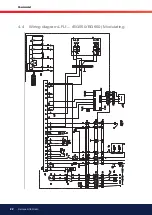

Note on 2-stage and modulating burners that during the

pre-purging period the damper opens to the set value

for air on stage 2 and just before the end of the pre-

purging period it goes down to the air setting for stage 1.

On some burners under 350kW the pre-purging mainly

takes place with the air damper set for stage 1.

NOTE! Applies only to gas burner control

LFL1...

When using LPG (Propane) the burner should be

connected for post-purging. Move the connection on

terminal 6 to terminal 7 in the base of LFL1.