6

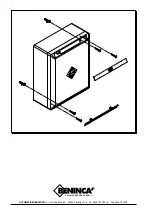

DA.C15 Control unit with microcontroller

The ”DA.C15” control unit with microcontroller is suitable for motors with up to 1500W power.

If the control unit is powered at 380V, it is advisable to replace the three 6.3A fuses located near the

power supply terminal board with the three 4A fuses in the envelope stuck to the central box.

Installation instructions.

a)

The electrical installation and functioning logic must comply with current standards.

b)

Keep the power cables (for the motor and power supply) away from the control cables (buttons,

photocells, radio). To avoid interference use two separate sheaths (see EN 60204-1 15.1.3).

c)

Check all the connections again before supplying voltage.

d)

Check that the Dip-Switch settings are as required.

e)

When voltage is supplied, the ”POWER” led should light up. If this is not the case, check the state

of the fuses and whether 230VAC 50Hz power is present between terminals 1 and 2 (INPUT 230VAC

- respect phase/neutral wire position).

f)

The N.C. inputs not used must be connected to the common ”+V”.

g)

If the direction of the motor rotation is not correct, invert the ”OPEN” - ”CLOSE” wires of the motor

as well as the wires of the ”FCA” - ”FCC” limit switches.

Input/Output functions

(1,2,3)

INPUT 230/380VAC= Control unit 230/380VAC 50Hz power supply

(respect phase/neutral wire position: 1= Neutral or L1,2= Phase or L2,3= L3)

(4,5,6)

SELEZIONE TENSIONE DI ALIMENTAZIONE

Connect terminals 4 and 5 if the control unit is powered at 230VAC

Connect terminals 6 and 5 if the control unit is powered at 380VAC

(7,8,9)

APRE/CHIUDE/COM= Connection to the corresponding 230/380VAC 50Hz motor terminals

(the earth wire (green/yellow) must be connected to the motor housing).

(10,11) LAMP230= Connection to the 230VAC blinker.

(12,13) OUT 24VAC= 24VAC auxiliary power supply output (1A max.).

(14,15) SCA= Output “Open gate indicator”, 24VAC.

The output of the LED changes according to the status of the control unit:

• Off with gate in the closed position

• Slowly flashing during the opening phase

• Rapidly flashing during the closing phase

• On with gate stopped in the open position

(16,17) +V= Common connection to all the control inputs.

(18)

ASA= Input of anti-crash device in the opening phase (normally closed contact): the opening of

the contact in the opening phase causes the movement reversion for a few centimetres and

then the stopping of the movement.

(19)

ASC= Input of anti-crash device in the closing phase (normally closed contact): the opening of

the contact in the closing phase causes the movement reversion for a few centimetres and

then the stopping of the movement.

(20)

FTC= Photocell receiver input (n.c. contact).

(21)

FCA= Limit switch input - Opening (n.c. contact).

(22)

FCC= Limit switch input - Closing (n.c. contact).

(23)

STOP= STOP button input (n.c. contact).

(24)

PED= PEDESTRIAN button input (n.o. contact)

(25)

P.P.= STEP-by-STEP button input (n.o. contact).

(26)

APRE= OPEN button input (n.o. contact).