99

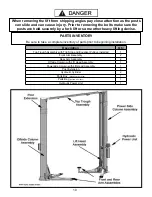

StEP 1

(Selecting Site)

Before installing your new lift, check the following.

1.

LIFt LoCAtIoN

: Always use architects plans when

available. Check layout dimension against floor plan

requirements making sure that adequate space if

available.

2.

oVERHEAD oBStRuCtIoNS

: The area where the

lift will be located should be free of overhead

obstructions such as heaters, building supports, electrical

lines etc.

3.

DEFECtIVE FLooR

: Visually inspect the site where

the lift is to be installed and check for cracked or

defective concrete.

4.

oPERAtING tEMPERAtuRE.

Operate lift only

between temperatures of 41° -104° F.

5. Lift is designed for

INDooR INStALLAtIoN oNLy.

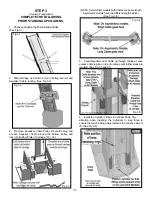

StEP 2

(Floor Requirements)

This lift must be installed on a solid level concrete

floor with no more than 3-degrees of slope. Failure

to do so could cause personal injury or death.

A level floor is suggested for proper use and

installation and level lifting. If a floor is of questionable

slope, consider a survey of the site and/or the possibility

of pouring a new level concrete slab.

t

Do Not

install or use this lift on any asphalt surface

or any surface other than concrete.

t

Do Not

install or use this lift on expansion seams

or on cracked or defective concrete.

t

Do Not

install or use this lift on a second / elevated

floor without first consulting building architect.

t

Do Not

install or use this lift outdoors.

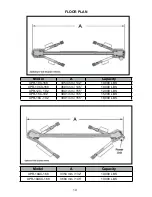

CoNCREtE SPECIFICAtIoNS

LIFt MoDEL CoNCREtE REQuIREMENtS

10,000 Lb Models

4” Min. Thickness / 3,000 PSI

12,000 Lb Models

6” Min. Thickness / 3,000 PSI

15,000 Lb Models

6” Min. Thickness / 3,000 PSI

18,000 Lb Models

8” Min. Thickness / 3,000 PSI

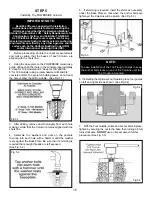

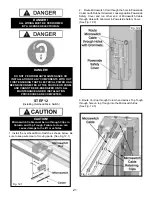

DANGER!

All models MUST be installed on 3000 PSI concrete only

conforming to the minimum requirements shown above.

New concrete must be adequately cured by at least

28 days minimum.

IMPoRtANt NotICE!

These instructions must be followed to insure proper installation and operation of your lift.

Failure to comply with these instructions can result in serious bodily harm and void product warranty.

Manufacturer will assume no liability for loss or damage of any kind, expressed or implied resulting

from improper installation or use of this product.

PLEASE READ ENtIRE MANuAL PRIoR to INStALLAtIoN !

t

Rotary Hammer Drill or Similar

t

3/4” Masonry Bit

t

Hammer

t

4 Foot Level

t

Open-End Wrench Set: SAE/Metric

t

Socket And Ratchet Set: SAE/Metric

t

Hex-Key / Allen Wrench Set

t

Large Crescent Wrench

t

Large Pipe Wrench

t

Crow Bar

t

Chalk Line

t

Medium Flat Screwdriver

t

Tape Measure: 25 Foot Minimum

t

Needle Nose Pliers

tooLS REQuIRED

IMPoRtANt NotE:

BendPak lifts are supplied with installation instructions and concrete fasteners meeting the criteria as prescribed

by the American National Standard "Automotive Lifts - Safety Requirements for Construction, testing, and

Validation" ANSI/ALI ALCtV-2006. Lift buyers are responsible for any special regional structural and/or seismic

anchoring requirements specified by any other agencies and/or codes such as the Uniform Building Code (UBC)

and/or International Building Code (IBC).

Summary of Contents for XpR-10AC-168

Page 25: ...25 25 ...

Page 28: ...28 ...

Page 32: ...32 32 OPTIONAL EQUIPMENT INSTALLATION ...

Page 42: ...42 42 ...

Page 43: ...43 43 ...

Page 52: ...52 52 ...

Page 74: ...74 ...

Page 75: ...75 ...