38

6. Push the

RAISE

button or rotate the control switch on

the power unit.

Important Note:

Allow (2) seconds between motor starts.

Failure to comply may cause motor burnout.

7. Stop before making contact with vehicle. Check arm

restraint pins for engagement. If required, slightly move

arm to allow restraint gear and pawl to mesh.

Do Not

hammer arm restraint pin down as this will damage the

restraint gear teeth.

8. Raise vehicle until tires clear the floor.

9. Stop and check adapters for secure contact at vehicle

manufacturer’s recommended lift points.

10. Continue to raise to desired height only if vehicle is

secure on lift.

11.

Do Not

go near or under a raised vehicle if all four

adapters are not in secure contact with vehicle at vehicle

manufacturer’s recommended lift points.

12. Repeat entire loading and raising procedures if

required.

13. Lower lift onto safety locks.

•

Do Not

enter work area or go under vehicle if safety

locks are not engaged.

•

CLEAR AREA

if vehicle is in danger of falling.

•

Do Not

position yourself between a wall and the lift.

If the vehicle falls in that direction, you may be severely

injured.

• Before attempting to lift pickup trucks or other truck

frame vehicles, be sure that:

t

Vehicle frame is strong enough to support its

weight and has not been weakened by

modification or corrosion.

t

Vehicle individual axle weight does not exceed

one-half lift capacity.

t

Adapters are in secure contact with frame at

vehicle manufacturers recommended lift points.

t

Vehicle is stable on lift and neither front nor “tail”

heavy.

t

The overhead switch bar will contact the highest

point on the vehicle.

WHILE uSING LIFt

• Avoid excessive rocking of vehicle while on lift.

• Always use safety stands as needed or when

removing or installing heavy components.

to LoWER tHE LIFt

1. Remove all tools or other objects from the lift area.

2. Raise lift off safety locks. Make sure you raise the lift

by at least two inches to allow adequate clearance for the

locks to clear.

3. Push safety lock release handle fully and hold.

4. Push LOWERING valve handle to lower. Note: Both

SAFETY LOCK release and LOWERING valve handles

must be held down simultaneously to lower lift. Do not

override self-closing lift controls.

5. Remain clear of lift when lowering vehicle. Observe

pinch point warning decals.

6. Remove adapters from under vehicle and swing arms

to full drive-thru position before moving vehicle.

7. If lift is not operating properly, Do Not use until

adjustment or repairs are made by qualified lift service

personnel.

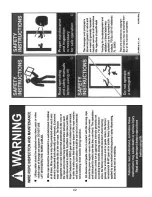

DANGER!

VISuALLy CoNFIRM tHAt ALL PRIMARy

SAFEty LoCKS ARE ENGAGED BEFoRE

ENtERING WoRK AREA.

Suspension components us on this lift are

intended to raise and lower lift only and are

not meant to be load holding devices.

Remain clear of elevated lift unless visual

confirmation is made that all primary

safety locks are fully engaged and the lift is

LOWERED onto the safety locks, Refer to

installation /operation manual for proper safety

lock procedures and /or further instruction.

WARNING!

When lowering the lift PAy CAREFuL AttENtIoN

that all personnel and objects are kept clear.

ALWAyS keep a visual line of site on the lift At ALL

tIMES. ALWAyS make sure that ALL LoCKS are

disengaged. If one of the locks inadvertently locks

on descent the lift and/or vehicle may disrupt

causing personal injury or death.

Summary of Contents for XpR-10AC-168

Page 25: ...25 25 ...

Page 28: ...28 ...

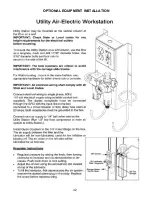

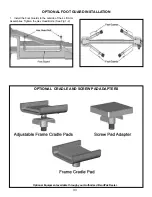

Page 32: ...32 32 OPTIONAL EQUIPMENT INSTALLATION ...

Page 42: ...42 42 ...

Page 43: ...43 43 ...

Page 52: ...52 52 ...

Page 74: ...74 ...

Page 75: ...75 ...