-8-

[ 3 ] MAIN CONTROLLER AND ARM INSTALLATION

The instructions given below are for mounting the main controller assembly on wood studs.

Should the PHOT-XIIs 505 be mounted in a manner other than what is specified here, the

wall and the strength of the hardware used must be checked and verified as being adequate to

withstand a 45kg shear load and a 200kg withdrawal force at each of the three ( 9 x 75mm) lag

screws. When using concealed wiring, a flush mounted junction box with the necessary conduit

and wiring must be pre-installed at 1165mm from the floor.

A. ARM MOUNTING BRAKET

Make sure the power supply is turned OFF at the circuit breaker panel.

1. Tape the wall mounting template to the wall, positioning it so that the holes for mounting plate

lag screws are aligned with the vertical studs.

NOTE :

Confirm that the location of concealed wiring matches to the access hole of wall plate

template.

2. Mark the hole locations for the arm mounting bracket lag screws.

3. Use a 3/16" (5mm) dia. drill to make a pilot hole approximately 50mm deep for each mounting

lag screws.

Do not use a drill larger than 5mm dia. for these holes.

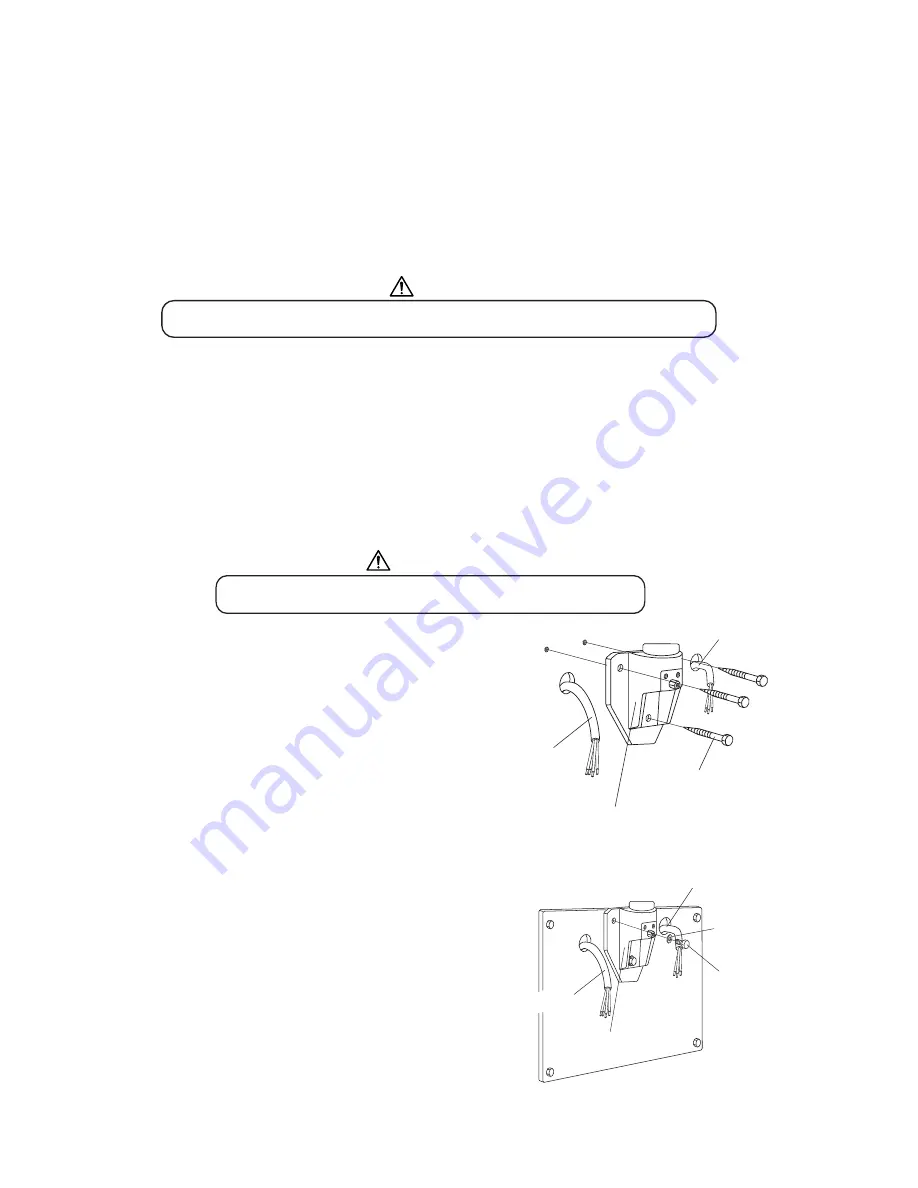

4. Using three lag screws ( 9 x 75mm) with washers in

top mounting holes and in lower mounting hole, mount

the arm mounting bracket on the wood stud.

(Fig.3-1)

WARNING

CAUTION

Fig.3-1

Arm Mounting Bracket

Installation

WALL PLATE INSTALATTION (OPTION)

1. Place the wire through the hole into the stud mount

wall plate and mount the plate to the stud with

four ( 9 x 75mm) lag screws.

DO NOT FULLY TIGHTEN.

2. Using three bolts (M8 x 20mm) with washers in top

mounting holes and in lower mounting hole, mount

arm mounting bracket to wall plate.

(Fig.3-2)

Arm Mounting

Bracket

Wires

( 9 x 75)

Lag Screw

Fig.3-2

Arm Mounting Bracket Installation

on Wall Plate (Option)

ø

ø

ø

ø

Arm Mounting

Bracket

(M8x20)

Bolt

Flat Washer

Wires

Interconnecting

Interconnecting

Power Supply

Power Supply

Wires

Wires

Summary of Contents for PHOT-X IIs 505

Page 2: ......

Page 35: ...NOTE...