4

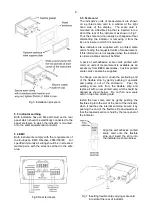

2.1 Controls

The indicators are controlled and calibrated via the

four front panel push button switches. In the

display mode i.e. when the indicator is displaying a

process variable, these push buttons have the

following functions:

P

While this button is pushed the

indicator will display the input current in

mA, or as a percentage of the

instrument span depending upon how

the indicator has been configured.

When the button is released the normal

display in engineering units will return.

The function of this push button is

modified when optional alarms are

fitted to the indicator.

▼

While this button is pushed the

indicator will display the numerical

value and analogue bargraph* the

indicator has been calibrated to display

with a 4mA

Φ

input. When released the

normal display in engineering units will

return.

▲

While this button is pushed the

indicator will display the numerical

value and analogue bargraph* the

indicator has been calibrated to display

with a 20mA

Φ

input. When released the

normal display in engineering units will

return.

E

No function in the display mode unless

the tare function is being used.

P +

▼

Indicator displays firmware number

followed by version.

P +

▲

Provides direct access to the alarm

setpoints when optional alarms are

fitted to the indicator and the ‘ACSP’

access setpoints in display mode

function has been enabled.

P + E

Provides access to the configuration

menu via optional security code.

Notes:

*

BA327NE

only

Φ

If the indicator has been calibrated

using the CAL function, calibration

points may not be 4 and 20mA.

3. CERTIFICATION

Both models have ATEX and IECEx gas and dust

certification. The main sections of this instruction

manual describes ATEX gas certification. ATEX

dust approval is described in Appendix 2 and

IECEx gas and dust certification in Appendix 3.

3.1 ATEX Ex nA certification

Notified Body Intertek Testing and Certification Ltd

have issued both instruments with a common Type

Examination

Certificate

number

ITS14ATEX48028X. This has been used to

confirm compliance with the European ATEX

Directive for Group II, Category 3GD equipment.

The instruments carry the Community Mark and,

subject to local codes of practice, may be installed

in any of the European Economic Area (EEA)

member countries and in the EEA EFTA states,

Iceland, Liechtenstein and Norway. ATEX

certificates are also acceptable in Switzerland and

Turkey. The European Commission's Blue Guide

lists the member states, overseas countries and

territories that have adopted harmonisation

legislation.

This section of the instruction manual describes

ATEX installations in explosive gas atmospheres

conforming with BS EN 60079-14:2008

Electrical

installations design, selection and erection

. When

designing systems for installation outside the UK

the local Code of Practice should be consulted.

3.2 Zones, gas groups and T rating

The indicators have been certified as Group II

Category 3G Ex nA ic IIC T5 Gc apparatus and

may be used in an ambient temperature Ta

between – 40°C to +70°C. This is non-sparking

apparatus complying with BS EN 60079-15

Equipment protection by type of protection 'n'

that

minimises the risk of arcs or sparks capable of

creating an ignition hazard occurring during

conditions of normal operation.

Special conditions for safe use are specified by the

Ex nA certificate indicated by the certificate

number's 'X' suffix. These state that the indicators

should be correctly mounted in a panel enclosure

complying with the requirements specified in

BS EN 60079-15:2010 for Equipment protection by

type of Protection 'n'. For Category 3 installations

in Zone 2 self or third party certified Ex n, Ex e or

Ex p panel enclosures may be used. Additional

requirement apply for non-metallic panel

enclosures.

BS EN 60079-17

Electrical installations inspection

and maintenance

permits live maintenance in Zone

2 if a risk analysis demonstrates that this does not

introduce an unacceptable risk. The removal of

covers [opening of Ex n enclosure] is permitted if