20

9. ACCESSORIES

9.1 Scale card

Both models have a window on the right hand side

of the display through which to view a scale card

showing the units of measurement such as

o

C,

mBar or RPM. New indicators are fitted with a

scale card showing the units of measurement

specified when the indicator was ordered, if the

units are not specified a blank scale card will be

fitted. A pack of scale cards pre-printed with

common units of measurement is available as an

accessory. These can easily be fitted to the

indicator on-site without opening the indicator

enclosure or removing it from the panel enclosure.

See section 5.5 of this instruction manual.

Less common units of measrement can be hand

printed onto the scale card using a variety of

techniques, or custom printed cards are available

from BEKA.

9.2 Tag information

New indicators can be supplied with tag or

application information laser etched onto the rear

of the instrument. This tag information is not

visible from the front of the instrument after

installation.

9.3 Stainless steel support plate

When a BA307NE or BA327NE indicator is

installed into an enclosure panel less than 1mm

thick or in a non-metallic enclosure panel, a

support plate may be required as explained in

section 5.2c of this manual. This plate prevents

the enclosure panel being distorted or creeping

when the indicator panel clamps are tightened and

ensures that the joint between the indicator and the

panel enclosure in which it is mounted remains

sealed.

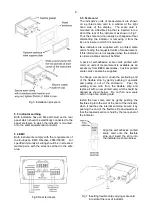

9.4 Alarms

CAUTION

These alarms outputs should not be used for

critical safety applications such as an

emergency shut down system.

Both models can be supplied with factory fitted

dual solid state, single pole alarm outputs. Each

alarm output may be independently conditioned as

a high or low alarm with a normally open or

normally closed output in the non-alarm condition.

When the 4/20mA current powering the indicator is

removed both alarm outputs will open irrespective

of configuration. The open circuit condition should

therefore be chosen as the alarm condition when

designing an alarm system. Fig 11 illustrates the

conditions available and shows which are fail safe.

When an alarm occurs an alarm annunciator on

the indicator's front panel is activated and if

required the numerical display can alternate

between the measured value and the alarm

channel identification ‘ALr1’ or ‘ALr2’.

CAUTION

The alarms are activated by the indicator’s

numerical display. Use of the Tare Function

‘tArE’ will change the numerical display, the

alarms will continue to function at the original

displayed value, but this will correspond to a

different input current.

Fig 11 Alarm outputs

Configurable functions for each alarm include

adjustable setpoint, hysteresis, alarm delay and

alarm accept.