IMPORTANT:

Always check driveline length during initial setup and when connecting to

a different tractor.

In the collapsed position the driveline should be approximately 2” from bottoming out to

prevent possible damage to the tractor or implement. When the driveline is in the

maximum extended position, the ideal minimum overlap of the two halves should be

approximately 6”

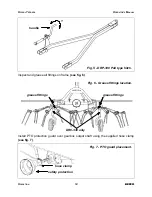

(see fig. 19)

.

If determined that the driveline is too long, follow these procedures to adjust the length:

1. Separate the two driveline halves. Connect one half to the tractor PTO and the other

half to the tedder.

2. On tedder DR0-330, raise and lower the tedder with the 3 point hitch to find the

position where the driveline is shortest. Hold the half shafts side by side and mark

the desired length on the outer female tube guard leaving a 1½” gap between the

end of the guard tube and bell guard.

3. Cut off both guard tubes the same amount as marked in step 2.

4. Shorten both drive tubes the same amount as guard tubes.

5. De-burr and clean filings from drive tubes and apply grease to outside of inner

telescoping tube.

6. Reassemble the driveline halves and connect to tractor and tedder. Raise and lower

tedder again to be sure driveline does not bottom out in its shortest position and has

a minimum overlap of 6” in the longest position.

7. Install both driveline safety chains. One should be hooked in a hole on the outer

driveline yoke shield and to the tractor to restrict outer shield rotation. The second

one should be hooked in a hole on the inner driveline yoke shield and to the

implement to restrict inner shield rotation.

If determined that the driveline is too short for your tractor, contact your local dealer.

M

AINTENANCE

27

BEFCO

R

OTARY

T

EDDERS

O

PERATOR

’

S

M

ANUAL

Fig. 19

MAX.

MIN.

min. 6"

min. 2"

Summary of Contents for DR0-330

Page 36: ......

Page 40: ...ROTARY TEDDERS RIGHT FRAME OPERATOR S MANUAL DR0 330 DRP 330 PARTS MANUAL 40 BEFCO 01 2012...

Page 54: ......