4. Attach the driveline chains to the tractor and to the tedder to keep the driveline

protection from turning. The chains should not be too tight.

5. Ensure the driveline has at least 2” from bottoming out in its shortest working

position and has the minimum 6” overlap in its longest working position. Refer to

Section 4.03

6

of this manual, if it is determined that the driveline is too long and

needs to be shortened. Contact your local dealer if it is determined that the driveline

is too short for your tractor.

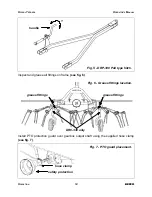

On pull type tedder model DRP-330, always make sure to adjust the tractor drawbar as

specified to ASAE standards to prevent failures

(see fig. 11)

. An improperly set hitch

could subject the driveline’s universal joints to undue stress.

The drawbar should be centered under the PTO shaft and secured so it cannot swing in

either direction.

CAUTION: Failure to conform to ASAE standards for drawbar PTO setup

dimensions can result in driveline damage and implement failure.

3.06 - Start Up

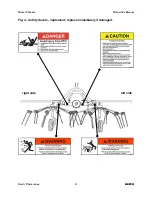

DANGER: The tedder must always be lowered to the ground before starting

tractor engine or engaging PTO lever.

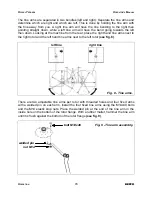

Lower tedder to the ground. With the engine idling, slowly engage the PTO drive. Move

the throttle lever until the PTO speed indicated on the tedder is obtained. PTO speed

may vary from 400 rpm to 540 rpm. Never exceed 540 rpm.

O

PERATION

18

BEFCO

R

OTARY

T

EDDERS

O

PERATOR

’

S

M

ANUAL

6

See Section 4.03 - Driveline, for instructions on how to determine correct driveline length and

procedures for shortening the driveline.

Fig. 11 - DRP-330 Drawbar adjustment.

14" for 540 rpm

6" to 12"

13" to 20" from ground

1"

min.

Summary of Contents for DR0-330

Page 36: ......

Page 40: ...ROTARY TEDDERS RIGHT FRAME OPERATOR S MANUAL DR0 330 DRP 330 PARTS MANUAL 40 BEFCO 01 2012...

Page 54: ......