25

The nameplate is located on top of the pump. This contains the pumps part number, horsepower voltage, phase,

and serial number, as well as other information. The start-up form located in the back of this manual contains a

place to record this data. The information should be recorded now so the pump does not have to be pulled again

later. The start-up form can be left in the control panel until station start-up is completed later.

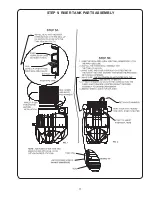

Step 17: RECORDING PUMP NAMEPLATE INFORMATION

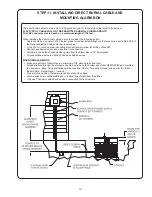

Step 18: INSTALLING

THE PUMP

The pump has an integral valve/upper

moveable and support fl ange. This will

guide the pump down the guide rail and

rest on the stop built into the POD (Pump

Orienting Device). Check to make sure the

check valve is aligned as shown before

lowering into the guide rail. When lowering

or lifting the pumps always use the lifting

device and appropriate lifting equipment.

NEVER MOVE THE PUMP

BY

THE POWER CORD!

ALWAYS INSTALL PUMP

BEFORE LEVEL CONTROL.

DO NOT DROP THE PUMP!

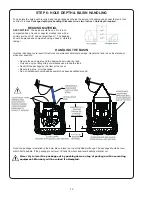

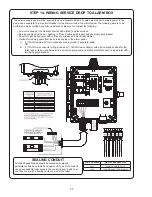

Step 19:

INSTALLING

THE LEVEL

CONTROL

The level control

has a unique shape.

This will fi t into the

pocket shaped to

accept it in the POD

next to the pump as

shown below. Lower

the level control into

the pocket as shown

below which will

automatically set the

correct height off the

basin bottom.