28

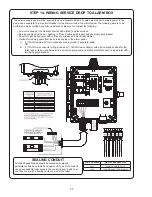

TROUBLE SHOOTING - EcoTRAN

CAUTION !

Always disconnect the pump from the electrical power source before handling.

If the system fails to operate properly, carefully read instructions and perform maintenance recommendations.

If operating problems persist, the following chart may be of assistance in identifying and correcting them:

MATCH “CAUSE” NUMBER WITH CORRELATING “CORRECTION” NUMBER

.

PROBLEM

CAUSE

CORRECTION

Pump will not run

1. Poor electrical connection, blown fuse,

tripped breaker or other interruption of

power, improper power supply.

2. Motor inoperative

3. Level control inoperative.

4. Insuffi cient liquid level.

1. Check all electrical connections for

security. Have electrician measure

current in motor leads, if current is within

±20% of locked rotor Amps, impeller is

probably locked. If current is 0, overload

may be tripped. Remove power, allow

pump to cool, then recheck current.

2. Check winding insulation (Megger Test)

and winding resistance. If check is

outside of range, dry and recheck, If still

defective, replace per service instructions.

3. Remove Level control and orient it

horizontally. If the pump still does not

operate, after rechecking all electrical

connections replace the level control.

4. Make sure liquid level is at least equal to

suggested turn-on point.

5. Recheck all sizing calculations to

determine pump type.

6. Check discharge line for restrictions,

including ice if line passes through or is

into cold areas.

7. Remove and examine check valve

for freedom of operation.

8. Open valve.

9. Check impeller for freedom of operation

security and condition. Clean impeller

cavity and inlet of any obstruction.

10. Check and clean anti-siphon.

11. Repair fi xtures as required to

eliminate leakage.

12. Check for leaks.

13. Check pump and level control

temperature limits and fl uid temperature.

Pump will not turn off

2. Motor inoperative

3. Level control inoperative.

5. Excessive infl ow or pump not properly sized

for application.

10. Pump may be airlocked.

Pump hums but does not run

1. Incorrect voltage

9. Impeller jammed or loose on shaft, worn or

damaged, impeller cavity or inlet plugged.

Pump delivers insuffi cient capacity

1. Incorrect voltage.

5. Excessive infl ow or pump not properly sized

for application.

6. Discharge restricted.

7. Check valve stuck closed

8. Shut-off valve closed.

9. Impeller jammed or loose on shaft, worn or

damaged, impeller cavity or inlet plugged.

10. Pump may be airlocked.

Pump cycles too frequently or runs

periodically when fi xtures are not in use

7. Check valve stuck closed

11. Fixtures are leaking.

12. Ground water entering basin.

Pump shuts off and turns on indepen-

dent of switch, (trips thermal overload

protector).

CAUTION!

Pump may start

unexpectedly. Disconnect power supply.

1. Incorrect voltage.

5. Excessive infl ow or pump not properly sized

for application.

9. Impeller jammed, loose on shaft, worn or

damaged, impeller cavity or inlet plugged.

13. Excessive water temperature.

Pump operates noisily or vibrates

excessively

2. Worn bearings or bent shaft

8. Debris in impeller cavity or broken impeller