Manual 2100-587J

Page

32 of 59

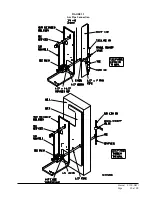

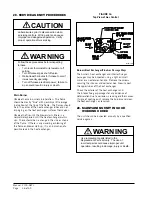

24. FILTERS

A 2" thick throwaway filter is supplied with each unit.

This filter is installed by removing the filter access

panel (see Figure 13).

Replacement filters are available through the local

dealer.

25. COMPRESSOR CONTROL MODULE

The compressor control module (CCM) is standard on

the models covered by this manual.

Features

Delay-on-Make Timer

Short Cycle Protection/Delay-on-Break

High Pressure Detection

HPC Status LED

Test Mode

Brownout Protection with Adjustment

Delay-on-Make Timer

A delay-on-make timer is included to be able to delay

startup of the compressor. This is desired when more

than one unit is on a structure so that all of the units

do not start at the same time which could happen

after a power loss or building shutdown. The delay-

on-make time period is 2 minutes plus 10% of the

delay-on-break time period. To ensure that all of the

FIGURE 13

Access Internal Filter

units do not start at the same time, adjust the delay-

on-break timer on each unit to a slightly different

delay time.

Short Cycle Protection/Delay-on-Break

An anti-short cycle timer is included to prevent short

cycling the compressor. This is adjustable from 30

seconds to 5 minutes via the adjustment knob. Once

a compressor call is lost, the time period must expire

before a new call will be initiated.

High Pressure Detection

High pressure switch monitoring allows for a lockout

condition in a situation where the switch is open. If

the high pressure switch opens, the CCM will de-

energize the compressor. If the switch closes again,

it will then restart the compressor after the delay-

on-break setting has expired on the device. If the

switch trips again during the same thermostat call,

the compressor will be de-energized and the alarm

terminal will be energized indicating an alarm. The

red LED will light and stay on until power is cycled

to the control or a loss of voltage is present at Y

terminal for more than ½ second.

Test Mode

By rapidly rotating the potentiometer (POT) clockwise

(see Figure 14), all timing functions will be removed

for testing.

MIS-3237

FILTER

FILTER

SERVICE

DOOR

Summary of Contents for WG Series

Page 11: ...Manual 2100 587J Page 11 of 59 FIGURE 2A Mounting Instructions for WG3S2...

Page 12: ...Manual 2100 587J Page 12 of 59 FIGURE 2B Mounting Instructions for WG4S2 and WG5S2...

Page 15: ...Manual 2100 587J Page 15 of 59 FIGURE 6 Common Wall Mounting Installations...

Page 25: ...Manual 2100 587J Page 25 of 59 FIGURE 11 Gas Pipe Connection...