Manual 2100-628

Page

12 of 24

WIRING – MAIN POWER

Refer to the unit rating plate for wire sizing information

and maximum fuse or circuit breaker size. Each

outdoor unit is marked with a “Minimum Circuit

Ampacity”. This means that the field wiring used must

be sized to carry that amount of current. Depending

on the installed KW of electric heat, there may be

two field power circuits required. If this is the case,

the unit serial plate will so indicate. All models are

suitable only for connection with copper wire. Each

unit and/or wiring diagram will be marked “Use Copper

Conductors Only”. These instructions

must be

adhered

to. Refer to the National Electrical Code (NEC) for

complete current carrying capacity data on the various

insulation grades of wiring material. All wiring must

conform to NEC and all local codes.

The electrical data lists fuse and wire sizes (75° C

copper) for all models including the most commonly

used heater sizes. Also shown are the number of field

power circuits required for the various models with

heaters.

The unit rating plate lists a “Maximum Time Delay

Relay Fuse” or circuit breaker that is to be used with

the equipment. The correct size must be used for

proper circuit protection and also to assure that there

will be no nuisance tripping due to the momentary high

starting current of the compressor motor.

The disconnect access door on this unit may be locked

to prevent unauthorized access to the disconnect. To

convert for the locking capability, bend the tab located

in the bottom left-hand corner of the disconnect

opening under the disconnect access panel straight

out. This tab will now line up with the slot in the door.

When shut, a padlock may be placed through the hole

in the tab preventing entry.

See “Start Up” section (page 17) for important

information on three phase scroll compressor start ups.

See Table 6 on page 23 for Electrical Specifications.

WIRING – LOW VOLTAGE WIRING

All 230/208V 1 phase equipment has dual primary

voltage transformers. All equipment leaves the factory

wired on 240V tap. For 208V operation, reconnect

from 240V to 208V tap. The acceptable operating

voltage range for the 240 and 208V taps are:

TAP RANGE

240

253 – 216

208

220 – 187

NOTE: The voltage should be measured at the field

power connection point in the unit and while

the unit is operating at full load (maximum

amperage operating condition).

18 guage copper, color-coded thermostat cable is

recommended. See Figure 7 on page 14 for thermostat

connections.

Low Voltage Connection

These units use a 24-volt AC low voltage circuit.

The “

RT

” terminal is the 24V transformer output,

and the “

R

” terminal is the 24VAC

hot

terminal for

the operation of the equipment. “

RT

” and “

R

” are

connected with brass jumper bar which can be removed

and “

RT

” and “

R

” connected to external NC (normally

closed) contact such as a fire/smoke detector that will

cause immediate shutdown of the equipment upon

activation.

“

C

” terminal is

grounded

.

“

G

” terminal is the

fan input

.

“

Y

” terminal is the

compressor input for cooling

“

W1

” terminal is the

1st stage electric heat

.

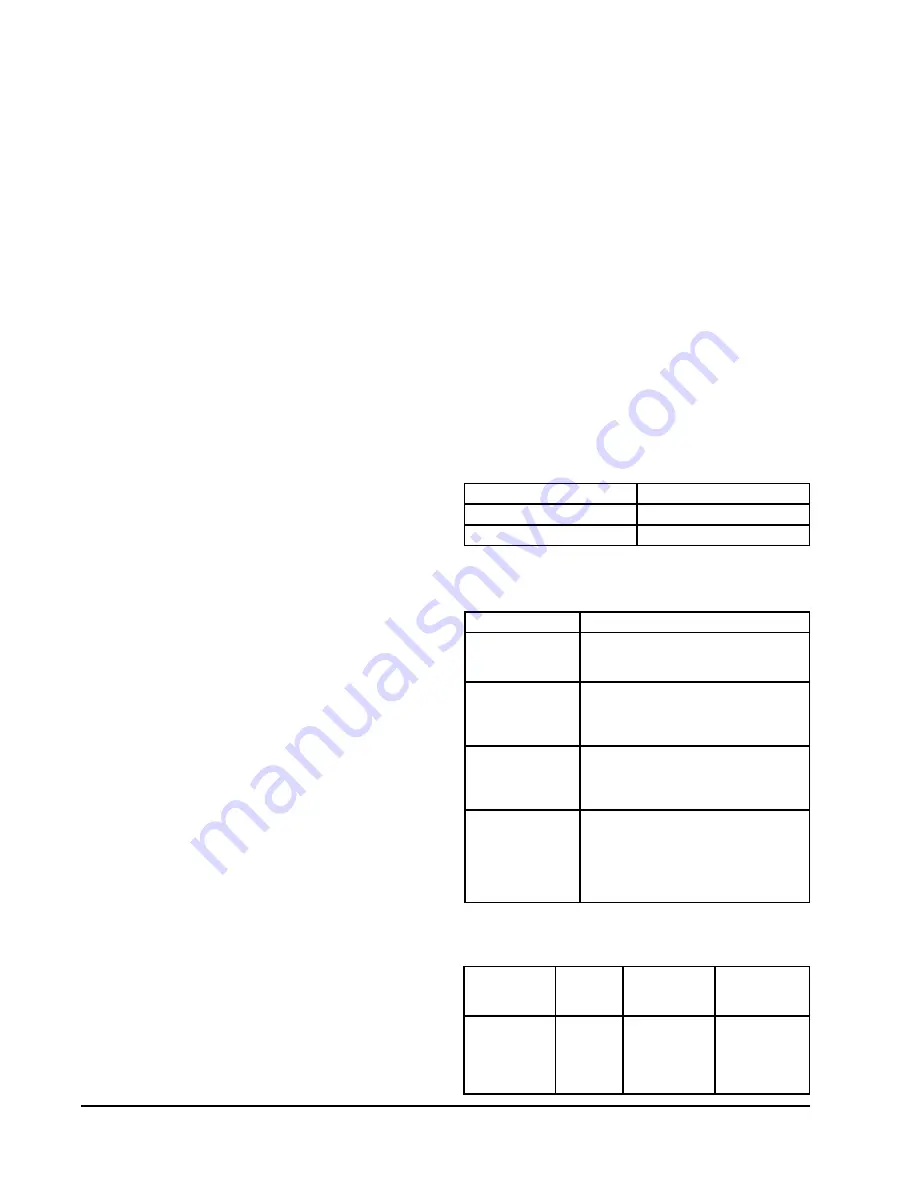

TABLE 3

THERMOSTAT WIRE SIZE

Transformer

VA

FLA

Wire Gauge

Maximum

Distance

(Feet)

55

2.3

20 gauge

18 gauge

16 gauge

14 gauge

12 gauge

45

60

100

160

250

TABLE 1

LOW VOLTAGE CONNECTIONS

FOR DDC CONTROL

Fan Only

Energize G

Cooling Mode

Energize Y, G

Heating Mode

Energize W1, G

Part Number

Predominate Features

8403-057

(TH3110D1040)

1 stage Cool, 1 stage Heat

Electronic Non-Programmable

Auto or Manual changeover

8403-058

(TH5220D1151)

2 stage Cool, 2 stage Heat

Electronic Non-Programmable

HP or Conventional (Default: HP)

Auto or Manual changeover

8403-059

(TH5220D1219/U)

2 stage Cool, 2 stage Heat

Electronic Non-Programmable

HP or Conventional (Default: AC)

Auto or Manual changeover

8403-060

(1120-445)

3 stage Cool; 3 stage Heat

Programmable/Non-Programmable

Electronic

HP or Conventional

Auto or Manual changeover

Dehumidification Output

TABLE 2

WALL THERMOSTAT