Bandit

Copyright 11/10

PAGE 6

MODEL 490

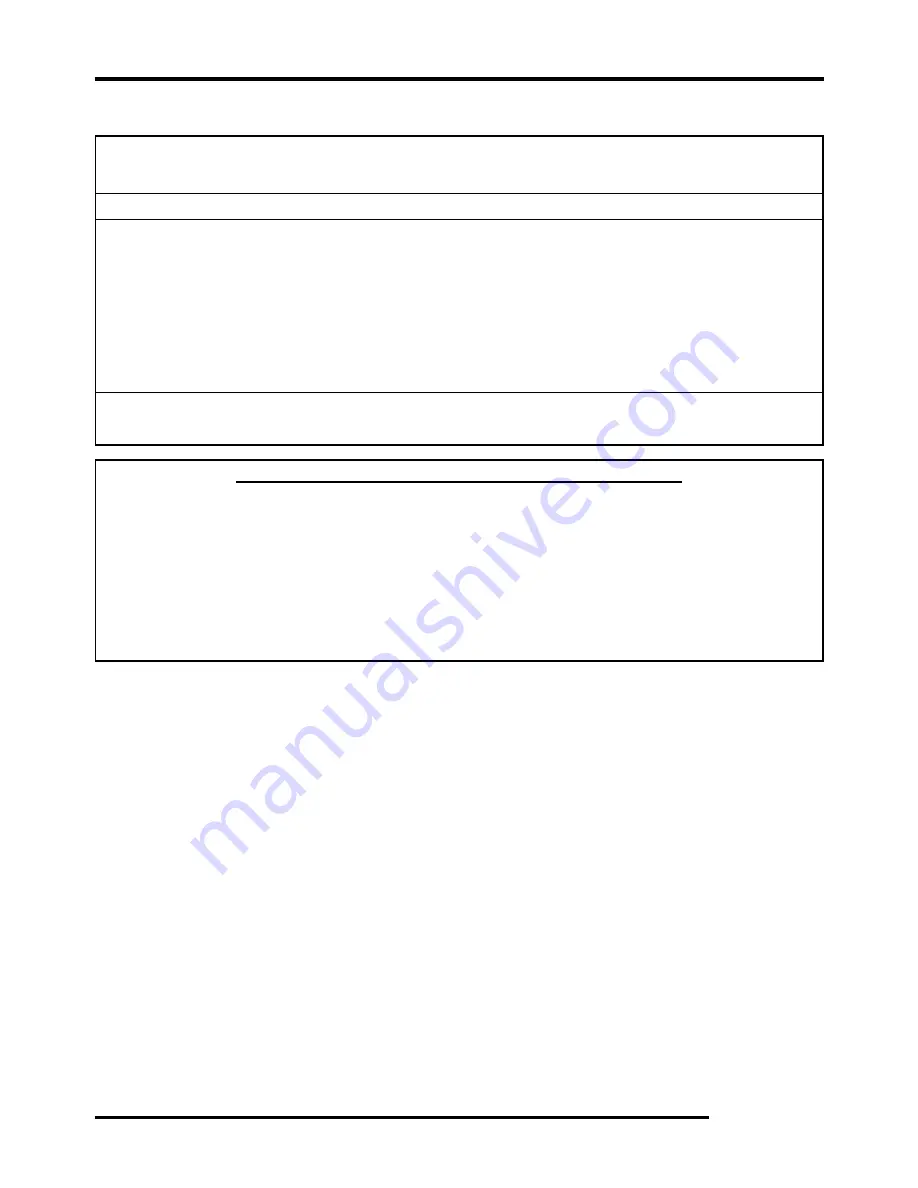

Chipper Drum Bearing Bolts

1/” - 1 NC

80 - 90

108 - 1

Drum Bearing Lock Collar

1/4” - 28 NF

15

20

Anvil

/8” - 16 NC

6 - 0

- 0

Knife Bolts

/8” - 16 NC

8 - 0

8 - 0

Engine Hold Downs

/8” - 16 NC

Sheave Bushing “SH”

1/” - 1 NC

9

1

Sheave Bushing “SK”

1/” - 1 NC

1

0

Sheave Bushing “SF”

/8” - 16 NC

0

1

Sheave Bushing “110”

1/” - 1 NC

1

19

BOLT TORQUE CHART

(THESE TORQUES ARE BASED ON DRY, CLEAN THREADS)

DESCRIPTION

BOLT SIZE

TORQUE (FT.-LBS.) TORQUE(Nm)

Before tightening bolts be sure you have the correct size bolt for the correct amount of torque.

Use only factory approved knives and hardware.

MAINTENANCE SECTION

MAINTENANCE SECTION

& 6 Lug Hubs (1/” - 0 Studs) ...................................90 - 10 ft.-lbs. Torque (1 - 16 Nm)

8 Lug Hubs (1/” - 0 Studs) .........................................90 - 10 ft.-lbs. Torque (1 - 16 Nm)

8 Lug Hubs (9/16” - 18 Studs) .....................................110 - 10 ft.-lbs. Torque (19 - 16 Nm)

8 Lug Hubs (/8” - 18 Studs) .......................................190 - 10 ft.-lbs. Torque (8 - 8 Nm) (Cone Nut)

8 Lug Hubs (/8” - 18 Studs) .......................................7 - ft.-lbs. Torque (7 - 1 Nm) (Flange Nut)

10 Lug Hubs (/” - 16 Studs) .....................................0 - 00 ft.-lbs. Torque (610 - 678 Nm)

(Consult axle manufacturers manual shipped with each machine for specific axle-stud-wheel combination lug nut torques.)

KEEP LUG NUTS PROPERLY TIGHTENED, CHECK NEW UNIT BEFORE OPERATION, CHECK

AGAIN AFTER 20-25 MILES (32-40 km) AND REGULARLY CHECK AT LEAST WEEKLY.

BASIC WHEEL TORQUE REQUIREMENTS (per mfg.)

PAINT CARE

To help keep up the appearance of your Bandit Equipment and reduce the possibility of surface

rust follow these steps:

1) The machine should be washed on a regular basis with a non-abrasive mild detergent and

then rinsed thoroughly. Do not pressure wash sensitive areas like: decals, gauges,

electronic devices, autofeed control, etc.

2) If a stone chip, paint scratch, or paint crack occurs - it should be repaired immediately.

Simply sand the edges of the damaged paint area, mask off the surrounding area and apply

primer and paint to the dry, clean, and warm surface. This will help keep the damaged area

from spreading or getting worse.

3) If you are unable to sand and mask the area, there are containers of primer and paint

available. A small brush can be used to touch up the area.

4) Also, primer and most colors of paint are available in aerosol spray cans to simply spray

over the effected area after it is cleaned, dry, and warmed. This method is not as reliable as

the process in step #.

It is also reported that some equipment owners polish their machine at least yearly, and keep good

mud flaps on their towing trucks.