Document ref.: IBVCP issue 1

Page 10 of 22

For the Equipment Installer

This section assists the system installer to install the equipment, and terminate and test the cabling. It

is assumed that all the cable runs have already been installed according to the system designer’s

specification.

To install this product you will need;

-

Tools for fixing the control panel on, or flush with, a vertical surface

-

A small flat-bladed screwdriver

-

A large Philips screwdriver for removing/replacing internal screws

-

A pair of wire cutters/strippers appropriate for the type of cable used

-

Ferules and ferruling tool for dressing the ends of cables (if stranded conductors are used)

-

Digital Multimeter for voltage and continuity tests

Installing Control Panels

47.

0

0.

0

363.

0

13.

5

396.

5

0.0

52.5

385.0

1.

Open the glazed door and remove the M6 screw(s) from the right-hand side of the Control Panel.

2.

To allow access to the two top locating holes in the rear of the unit, remove the two M6 locating

screws from the upper Termination Panel and drop it down.

3.

Fit the AssureCare Control Unit to the wall using suitable fixings.

Note: The weight of a 64 Way unit with batteries fitted is 26Kg, and a 128 Way unit weighs 37kg.

4.

Ensure all connectors are terminated correctly at the Termination Panel according to the system

designer’s specifications, and then relocate the upper Termination Panel using the M6 screws.

It is

very important that each conductor is correctly identified before being terminated. Incorrect

connections can damage this equipment.

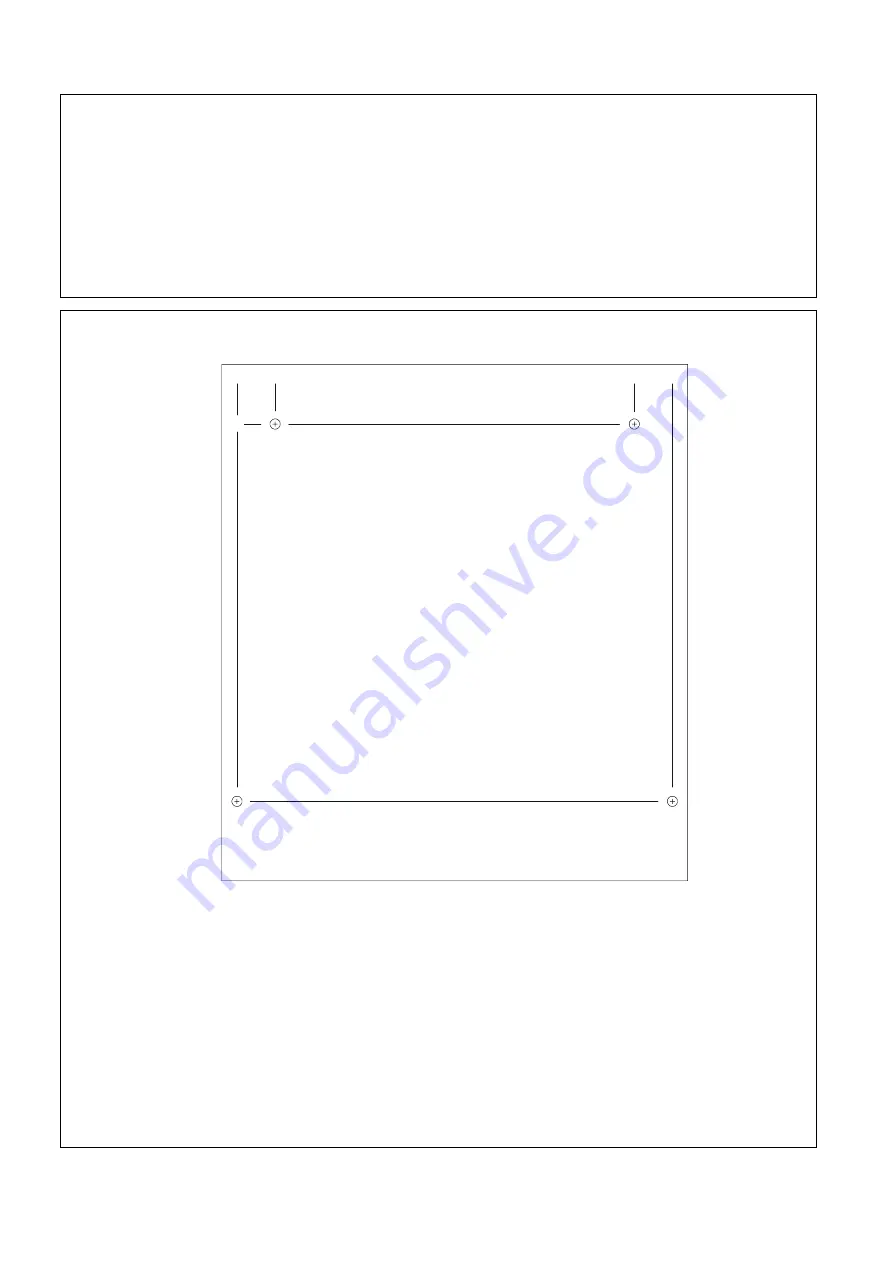

Diagram Showing Hole Centres For Mounting 64 Way Control Unit

(128 Way Control Unit shown on next page)