FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

15

CLEANING AND MAINTENANCE

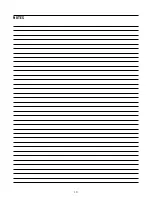

Parts List – Y800

ITEM

PART #

QTY

DESCRIPTION

1

21910330

1

ASSY, BOTTOM DOOR Y600/800

2

21910331

1

ASSY, TOP DOOR Y600/800

3

A8057K

1

BOTTOM TRIM

4

A4980T

1

CONTROL PANEL SLEEVE, SS

5

21910288

1

PANEL, FRONT CONTROL SIDE

6

A8056K

1

TOP TRIM

7

21910289

1

PANEL, FRONT RT SIDE

8

21910332

1

WELDMENT, LOWER DOOR ARM LT

9

21910316

1

WELDMENT, LOWER DOOR ARM RT

10

Q2025A

10

BOLT, 1/4-20 X 3/4 HEX HD ZINC

11

21910310

1

WELDMENT, TOP DOOR ARM LEFT

12

Q2401A

2

NUT, HEX 9/16-18

13

S3276A

1

DOOR SPRING ARM, 2.78” BOTTOM

14

Q3007A

1

WASHER, 9/16 SPLIT LOCK

15

S3007A

2

BUSHING ASSY, PTFE .5/.63 X .56

16

Q3010A

4

WASHER, 3/8-7/16 X 1” X 5/64 FLAT

17

Q2301A

1

BOLT, 3/8-16 X 9/32 X 1 SHOULDER

18

A3079K

2

FLAME DIVERTER SLIDE (35”)

19

A8035K

2

HANGER, FLAME DIVIDER

20

A8030T

4

FRAME ASM, HEARTH SUPPORT

21

A4132Z

1

HEARTH LINER SHEET, 36 X 39.25

22

A4133Z

1

HEARTH LINER SHEET, 36 X 20.75

23

A8036K

1

HANGER, FLAME DIVIDER CENTER

24

T1381A

3

STONE HEARTH, AWMCO 36” X 20” X 2”

25

S3134A

5

BUSHING, .81/.88 ID X 1 X 1.25 OD

26

S3133A

5

SLEEVE, DURALON .75 ID X .88 OD

27

A8017K

2

ANGLE, DOOR JAM BOTTOM

28

A8016K

2

ANGLE, DOOR JAM

29

R3115A

1

FLUE DEFLECTER

30

U1356A

2

PUSH-PULL PLATE

31

S1005A

2

KNOB, PUSH-PULL 3/8-16 BLK

32

8808902

1

NAMEPLATE, BAKERS PRIDE, DECK OVENS

33

21910312

1

WELDMENT, TOP DOOR ARM RIGHT

34

A8061K

1

COVER, HEARTH TRIM

35

A8082K

1

COVER FRONT LEFT ACCESS DOOR

36

S1004Y*

1

LEG, 30” [SET OF 4]

37

S1120Y*

1

LEG & CASTER 30” [SET OF 4]

38

S1003Y*

1

LEG, 16” [SET OF 4]

39

S1119Y*

1

LEG & CASTER 16” [SET OF 4]

40

M1242P

1

CONTROL ASSY, Y600

41

N5014A

1

NIPPLE, 1/2” X 5”, BLK PIPE

42

N3021A

2

REDUCING ELBOW, 3/4” X 1/2” 90° BLKSTL

ITEM

PART #

QTY

DESCRIPTION

43

N5232A

1

NIPPLE, 3/4” X 6-3/4” BLK PIPE, 3/4 OFFSET

44

N3002A

1

TEE, 3/4” X 3/4” X 1”, BLK PIPE REDUCING

45

K1332B

2

BACK COVER PATCH, SS [

46

N3008A

2

BUSHING, 1” X 3/4” REDUCING, BLK PIPE

47

N3022A

2

PLUG, 3/4” STEEL PIPE, W/1/2” SQ REECESS

48

N5252A

1

NIPPLE, 3/4” X 36”, BLK PIPE

49

N3007A

1

COUPLIING, 1/X3/4” REDUCING, BLK PIPE

50

N5009A

6

NIPPLE, 1/2” X 15/16”, BLK PIPE

51

N5220P

1

NIPPLE, 3/4” X 37-1/4”, BLK PIPE

52

300235

2

3/4” BLK STL UNION

53

N5218A

1

NIPPLE, 3/4” X 3” BLK STL

54

N3004A

1

ELBOW, 3/4” 90° BLK STL

55

N5213A

1

NIPPLE, 3/4” X 1-1/2” BLK STL

56

N3012A

1

REDUCING TEE, 1/2” X 1/2” X 3/4” BLK STL

57

L5001A

2

INSPIRATOR, #3 BLK

58

L5124T

1

BURNER ASSY, LH

59

L5125T

1

BURNER ASSY, RH

60

N3009A

4

1/2” BLK STL UNION

61

R3004A

2

SPUD HOLDER #3

62

R3006A

2

LOCKING DISK, SPUD

63

R3005A

2

ADJUSTING DISK #3 SPUD

64

R3117P

2

ORIFICE, #25 NAT, #3 SPUD

65

R3129P*

2

ORIFICE, #43 LP, #3 SPUD

66

A4143K

1

PILOT MOUNTING BRACKET

67

M1265A

1

THERMOPILE, Q313

68

Q1401A

2

SCREW, 10-32 X 1/2” PAN HD

69

M1220A

1

PILOT BURNER NAT

70

M1245A

* 1 PILOT BURNER LP

71

S1056A

1

KNOB, THERMOSTAT, 650 “F”, GAS BLACK

72

M1005A

1

THERMOSTAT, 650°F, FDTH

73

N3068P

1

PRESSURE TAP ASSY

74

M1242P

1

CONTROL ASSY BMVR NAT

75

M1248P*

1

CONTROL ASSY BMVR LP

76

A8006K*

1

BRICK LINED SUPPORT BRACE

77

T1375A*

8

BAKING DECK, CERAMIC

78

S3275A

1

DOOR SPRING ARM, 2.78”

* INDICATES NOT SHOWN

Summary of Contents for SUPER DECK Y-600

Page 21: ...19 NOTES ...