FLOOR MODEL ELECTRIC DECK OVEN OPERATION MANUAL

5

INSALLATION INSTRUCTIONS

Electrical Connection

General Instructions

a) Only a licensed electrician should make the

electrical connections.

b) Make sure electrical supply corresponds with that

specified on the rating plate.

c) Only use copper conductors rated at 90°C

suitability sized for the electric current drawn.

d) All pole disconnect(s) must be provided by the

installer.

E(PBR) – 3836 – 8(12) Power and Current per Deck

Power Supply

Volts (Phase)

E(PBR) – 5736 – 8(12) Power and Current per Deck

KW

L1 (amp)

L3 (amp)

L2 (amp)

N (amp)

KW

L1 (amp)

L3 (amp)

L2 (amp)

N (amp)

8.0

38.6

38.6

208(1)

12.0

57.8

57.8

8.0

21.0

25.0

21.0

208 (3)

12.0

33.5

33.3

33.5

7.3 – 8.7

33.3-36.3

33.3-36.3

220-240 (1)

11.0-13.0

50.0-54.6

50.0-54.6

7.3 – 8.7

18.0-19.7

21.5-23.5

18.0-19.7

220-240 (3)

11.0-13.0

29.0-31.6

28.9-31.5

29.0-31.6

7.3 – 8.7

16.7-18.2

16.7-18.2

440-480 (1)

11.0-13.0

25.0-27.3

25.0-27.3

7.3 – 8.7

9.0-10.0

10.8-11.8

9.0-10.0

440-480 (3)

11.0-13.0

14.5-15.8

14.4-15.7

14.5-15.8

8.0

35.0

35.0

400-Y (1)

12.0

52.3

52.3

8.0

8.38

13.0

13.0

4.2

400-Y (3)

12.0

17.5

17.4

17.4

0.1

NOTE: EACH OVEN REQUIRES A SEPARATE CONNECTION !

e) When installed, unit must be electrically grounded

in accordance with the local codes and/or the latest

edition of the National Electrical Code ANSI/NFPA

No. 70 in USA or Canadian Electrical Code, CSA

Standard C22.1, Part 1 in Canada.

f) FOR CE UNITS: The appliance must be connected

by an earthing cable to all other units in the

complete installation and thence to an independent

earth connection in compliance with EN 60335-1

and/or local codes. If flexible line cordage is used

to connect the equipment, it should be a minimum

of H07RN-F type conforming to EN60335-1 and/or

local codes.

Overexposure to smoke or fumes may cause

nausea and dizziness. Be sure the oven is placed

in a well ventilated area.

CAUTION

Field Connections

a) Remove all screws and vent knob from the control

panel(s). Pull control panel out at the bottom,

then down and out from the vent rod. Slip the right

flange hole of the control panel back onto the vent

rod, then replace the vent knob to keep the control

panel in an open and secure position.

b) Remove all screws from the left access panel(s),

then pull forward and out of the oven.

Stacked ovens only!

In all but the top oven, punch four 1 1/2” diameter holes

in each of the top covers, utilizing the 1/8 locating holes.

(See Fig. 5b)

c) Feed power cable (supplied by the customer) through

the access hole at the left side (see Fig 5g) or at the

bottom (see fig. 5h) of the oven and pull the cable to

the front of the oven where it may be attached to the

opening in the oven frame. See fig. 5i).

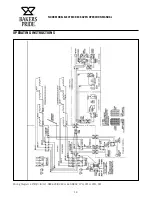

d) Following the appropriate wiring diagram conforming

to the rating plate, connect the power supply leads

to the field wiring terminal block (see fig. 5j). The

ground wire should be connected to the grounding

lug (see fig. 5k) attached to the oven frame.

e) For single phase 2-wire or three phase 3-wire

supplies, the controlling branch circuit is designed

to operate at 208-240 volts AC and is pre-wired at

the factory between L1 and L2 of the field wiring

terminal block.

Summary of Contents for EB series

Page 21: ...19 NOTES ...