6 | Baker Hughes

Copyright 2020 Baker Hughes Company. All rights reserved.

Introduction

The following instructions are designed to assist maintenance

personnel in performing most of the maintenance required on

the 37002 Series valve. Baker Hughes has highly skilled service

people around the world available for startup, maintenance and

repair of our valves and component parts. In addition, a regularly

scheduled training program is conducted to train customer service

and instrumentation personnel in the operation, maintenance and

application of our control valves and instruments. Arrangements

for these services can be made through your local Baker Hughes

Representative. When performing maintenance use only Baker

Hughes replacement parts. Parts are obtainable through your

local Masoneilan Representative. When ordering parts always

include Model and Serial Number of the unit being repaired.

These installation and maintenance instructions apply to all

sizes and ratings of the Masoneilan 37002 Series control valves,

regardless of the type of trim used. The model number, size and

rating of the valve are shown on the identification tags located

on the actuator. Refer to Figure 1 to identify valve nomenclature.

Unpacking

Care must be exercised when unpacking the valve to prevent

damage to the accessories and component parts. Should any

problems arise contact your Baker Hughes Representative or

Sales Office.

Installation

1. The valve is flangeless and has a rating of 300 lb ANSI. It

may be installed between machined flanges of the following

ANSI standards; 125 lb., 150 lb., 250 lb.. and 300 lb. ANSI

flanges as well as DIN (ND) 10, 16, 25 and 40 metric flanges.

2. Before installing the valve in the line, clean piping and

valve of all foreign materials, such as welding chips, scale,

oil, grease or dirt. Gasket surfaces should be thoroughly

cleaned to ensure leak proof joints.

3. To allow for inline inspection, maintenance and removal of

the valve without service interruption, provide a manually

operated stop valve on each side of the valve with a manually

operated throttling valve mounted in the bypass line.

4. The valve may be installed in the line so that the control

substance will flow in either direction. However, the actuator

must be located in one of the recommended positions

shown in Figure 1.

CAUTION

CAUTION

WARNING

DANGER

Prior to installing the valve in the line, this section

should be completely reviewed and understood.

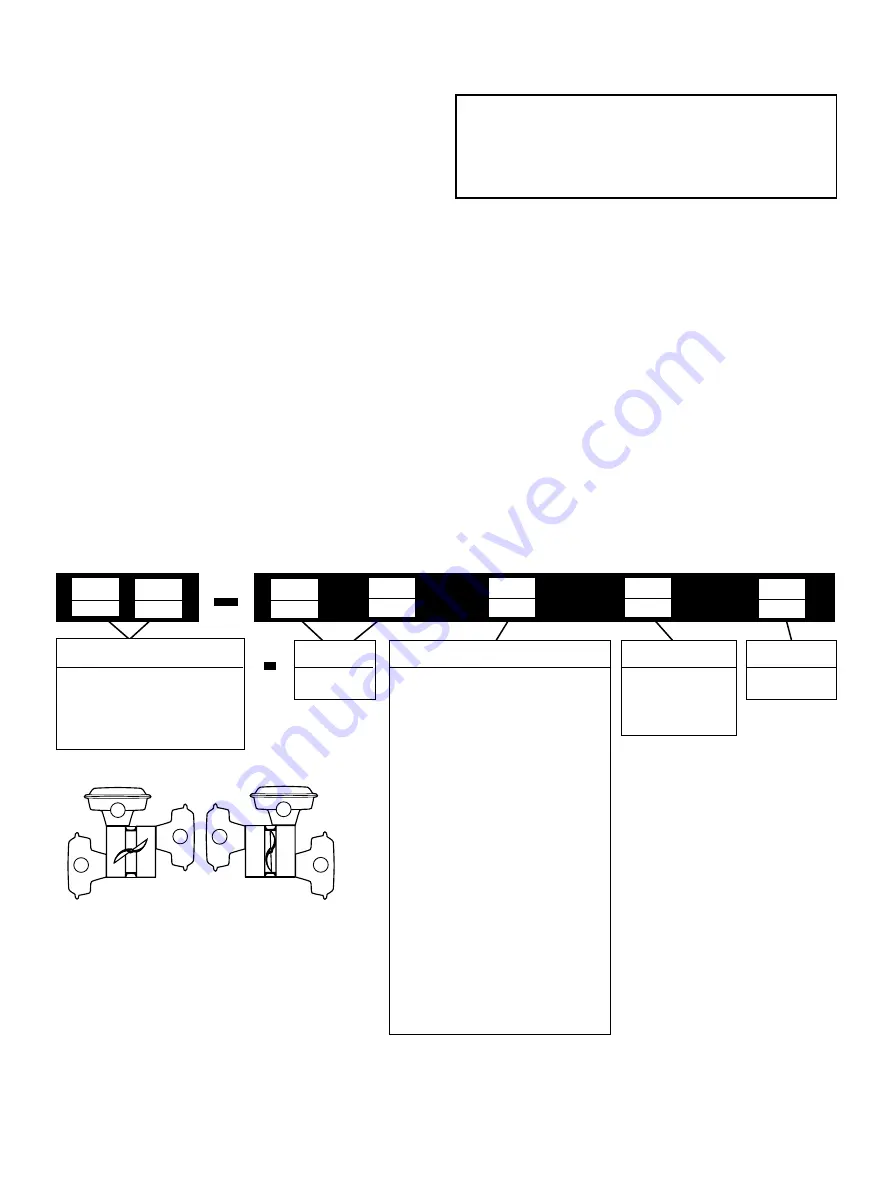

Numbering System

4th

3rd

33. Spring Diaphragm

(Air-To-Extend action

only, with or without

auxiliary handwheel)

2nd

7

2nd

1st

3

1st

3

5th

2

Actuator Type

1. Unlined

2. Elastomer

Lined

Bore Type

0. Undefined

1. Horizontal above centre.

Valve closes on stem extension

(air-to-close action)

2. Horizontal above centre.

Valve opens on stem extension

(air-to-open action)

*3.Vertical above centre.

Valve closes on stem extension

(air-to-close action)

*4. Vertical above centre.

Valve opens on stem extension

(air-to-open action)

5. Horizontal below centre.

Valve closes on stem extension

(air-to-close action)

6. Horizontal below centre.

Valve opens on stem extension

(air-to-open action)

*Standard actuator mounting arrangement

Actuator Mounting

2

Design Series

Body Series

37

5

1

3

6

4

2

Air-to-Close

Air-to-Open

Actuator in front of line

Unnumbered actuator positions above same as

numbered positions when valve is rotated 180° in line.

Figure 1