12 | Baker Hughes

Copyright 2020 Baker Hughes Company. All rights reserved.

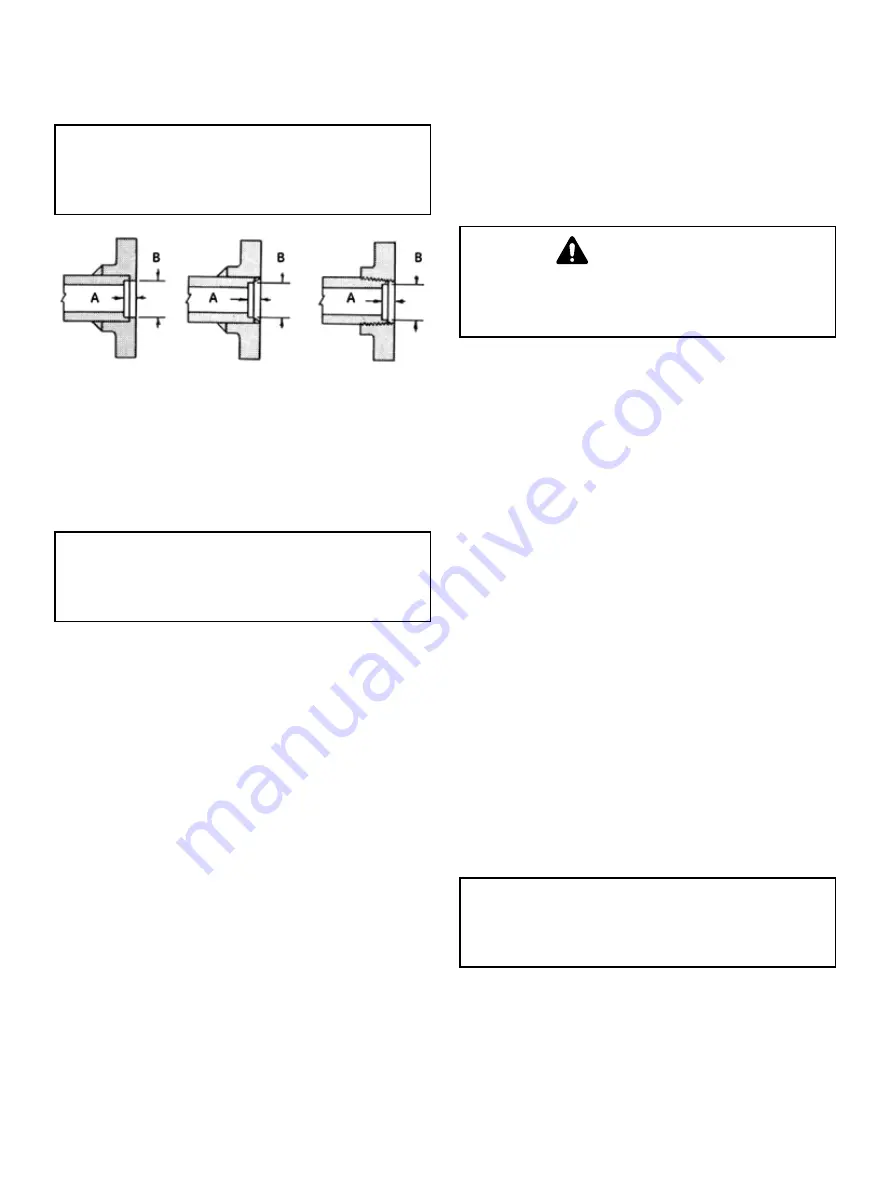

Weld Neck Flanges

150 lb and 300 lb ANSI weld neck flanges have standard bore

which matches 37000 Series MiniTork Butterfly valve bore.

CAUTION

CAUTION

WARNING

DANGER

Slip on and screwed flanges not recommended for

lined valves.

Figure 10

Actuator Air Piping

The MiniTork II actuator is designed to accept 1/4“ NPT air supply

piping. Use 1/4“ 0.D. tubing, or equivalent for all air lines. If the air

line exceeds 25’ in length or if the valve is equipped with volume

boosters, 3/8“ tubing is preferred. All connections must be free

of leaks.

CAUTION

CAUTION

WARNING

DANGER

Do not exceed loading pressure indicated on the

warning tag located on the diaphragm cover.

Changing Actuator Position

For each valve action, air to open or air to close, the actuator

and bracket may be mounted in any one of three recommended

positions (See Figure 1). Actuator position is usually determined

by adjacent piping, obstacles of various types or air piping

arrangements. If for example, the valve orientation is Position

6, but the valve must be installed in Position 2, simply rotate the

entire unit 180° around the axis of the shaft and install in the line. In

such a case, no disassembly is required other than repositioning

gauges so that they are not upside down. However, if the valve

orientation must be changed from Position 2 to Position 4, partial

disassembly is required. Depending on whether the valve is or is

not equipped with the handwheel and whether the valve is lined

or unlined, select the appropriate section in this instruction and

proceed.

Changing Actuator Action

For the positions shown in Figure 1, the valve action is air to

open or air to close. In both cases the actuator stem extends with

admission of air to the actuator. Changing valve action requires

partial disassembly in repositioning the actuator to the other hole

in the bracket. If the valve is equipped with a handwheel, it must

be repositioned to the opposite side of the bracket.

Note: The handwheel is always installed so it operates

against the actuator spring force. The handwheel is always

located on the same side of the bracket as the actuator

(See Figures 12 and 13). Depending on whether the valve

is or is not equipped with the handwheel and whether the

valve is lined or unlined, select the appropriate section on

disassembly and proceed.

Maintenance

CAUTION

CAUTION

WARNING

DANGER

Prior to performing maintenance on the valve, isolate

the valve, vent the process pressure and shut off all

electrical signal air and supply lines to the unit.

This section is primarily addressed to recommended routine

maintenance required on the valve which does not require

complete disassembly. Routine maintenance is limited to the

packing box and diaphragm replacement.

Packing Box

Packing box maintenance is one of the principal chores of

routine servicing. Tightness of the packing is obtained through

compression which is achieved by evenly tightening packing

stud nuts (23A) against a packing flange (22). Care must be

taken not to over tighten as this could prevent smooth operation

of the valve. If all compression is used up and the valve leaks

around the stem, new packing is required.

Note: If replacement of all packing is required, the valve

must be disassembled. Refer to appropriate section.

The following procedure should be used for temporary repairs

only.

A. Loosen and remove packing flange stud nuts (23A).

B. Slide packing flange (22) and packing follower (8)

down the shaft.

Note: As a temporary repair, it may be desirable

to simply add more packing, since removal of any

packing while the valve is assembled to the actuator is

difficult. In addition, only one or two pieces of packing

can be removed without disassembly. String packing,

compatible with the service, can be used as a temporary

repair, however it must be replaced with the correct

packing as soon as possible.

C. Add or replace packing as desired.

CAUTION

CAUTION

WARNING

DANGER

Do not over-tighten. Nuts should be tightened only

enough to stop leakage.

D. Slide packing follower (8) and packing flange (22)

back into position.

E. Replace and evenly tighten packing flange stud nuts

(23A).

F. Place valve back in service and check for leaking.