22

22

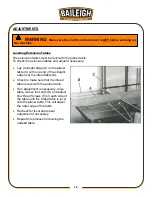

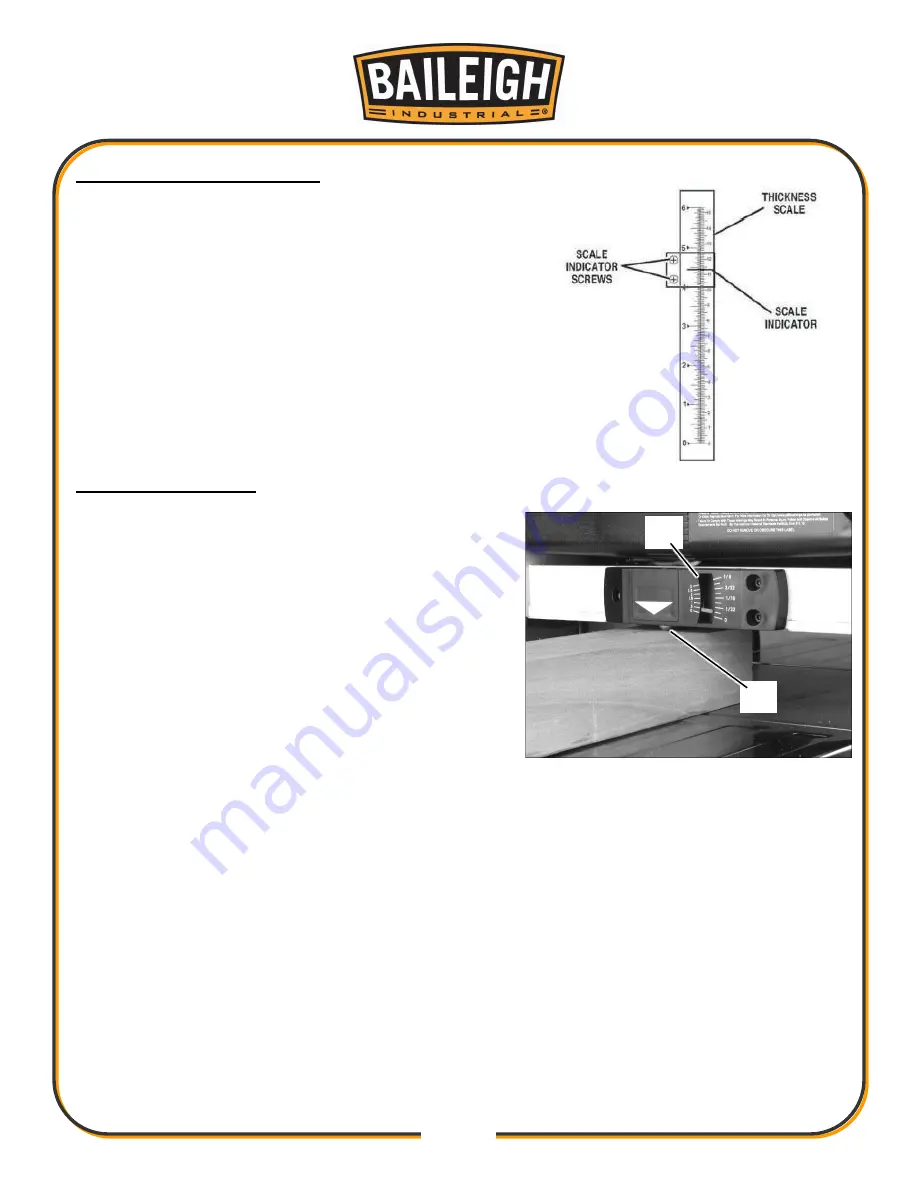

Thickness Scale Adjustment

The thickness scale, located on the right of the planer,

shows the thickness of the finished workpiece.

•

To make sure the scale is set properly, run a piece of

wood through the planer and measure the thickness of

the wood.

•

If the scale is out of alignment, loosen the two round

head screws (A) holding the scale indicator (B) and

adjust the thickness indicator to the correct setting.

•

Make sure to tighten the two screws once the

adjustment is complete.

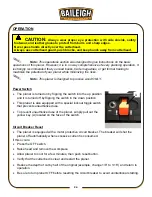

Cutting Depth Gauge

The cutting depth gauge provides a quick method for

setting depth of cut. The bottom of the gauge ball has

been set even with the cutterhead knives.

1. With the machine OFF, insert workpiece far

enough (about 2-inches) that it lies beneath the

gauge ball (A). Verify that the workpiece lies flat on

table.

2. Lower the cutter head until ball contacts workpiece

and engages the depth scale, as shown.

a. As you lower the cutter head, the needle on

the depth of cut scale will move showing

how much material will be removed in that pass.

3. Continue lowering until desired cut depth is shown on the scale (B). Remove the workpiece.

4. Start planer and insert workpiece, allowing it to push past gauge ball and continue feeding

through machine.

5. Refer to thickness scale to lower head to desired depth of cut for the next pass.

A

B

Summary of Contents for IP-1306

Page 38: ...35 35 PLANER PARTS DIAGRAM A...

Page 43: ...40 40 MOTOR PARTS DIAGRAM B...

Page 47: ...44 44 NOTES...