21

21

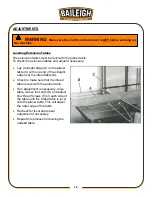

To rotate or change cutter tip inserts:

1. Face the rear of the machine. Remove

the Dust Port.

2. Use the handle to lower the cutterhead

assembly down to about 2” (50.8mm) on

the scale.

3. Insert the supplied Hex wrench through

the hole located on the side of the

machine above the Repeat Cut slider.

4. Rotate the cutterhead to a position where

a cutter tip is visible. (You may have to

raise or lower cutterhead to be able to

insert the Hex wrench into the

cutterhead)

5. While holding the hex wrench to prevent

cutterhead rotation, remove the cutter tip screw

using the provided Torx T-wrench allowing the tip to

be removed.

6. Carefully clean all dust and dirt off the cutter tip and

the cutterhead seat.

7. Replace or rotate the cutter insert so a fresh sharp

edge is facing outward. If available, use pitch

remover to be sure all wood residue is off the

cutterhead, cutter insert, and screws, before

attempting to rotate or replace them. Using a shot

of compressed air is also helpful. Be sure to wear

safety glasses when using compressed air.

8. Lubricate the Torx screw threads with light machine oil and wipe the excess oil off the

threads. Install cutter tip insert and torque the Torx screw to 48-50 inch/ pounds.

Note: Proper cleaning of tips and cutterhead is critical to achieving a smooth

finish. Dirt or dust trapped between the cutter insert and cutterhead will slightly raise the cutter

insert and make noticeable marks on your workpiece the next time you plane.

Summary of Contents for IP-1306

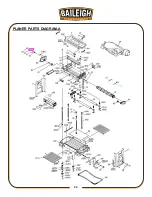

Page 38: ...35 35 PLANER PARTS DIAGRAM A...

Page 43: ...40 40 MOTOR PARTS DIAGRAM B...

Page 47: ...44 44 NOTES...