บริษัท เอดีดี เฟอร์เนส จ ำกัด

ADD FURNACE CO.,LTD.

44 ซอยบรมราชชนนี

70 ถนนบรมรำชชนนี แขวงศำลำธรรมสพน์ เขตทวีวัฒนำ กรุงเทพฯ 10170

โทร

: 02-888-3472

โทร

:

ออกแบ

บ

:

08-08-170-170

แฟกซ์

: 02-888-3258

https://www.add-furnace.com E-mail:

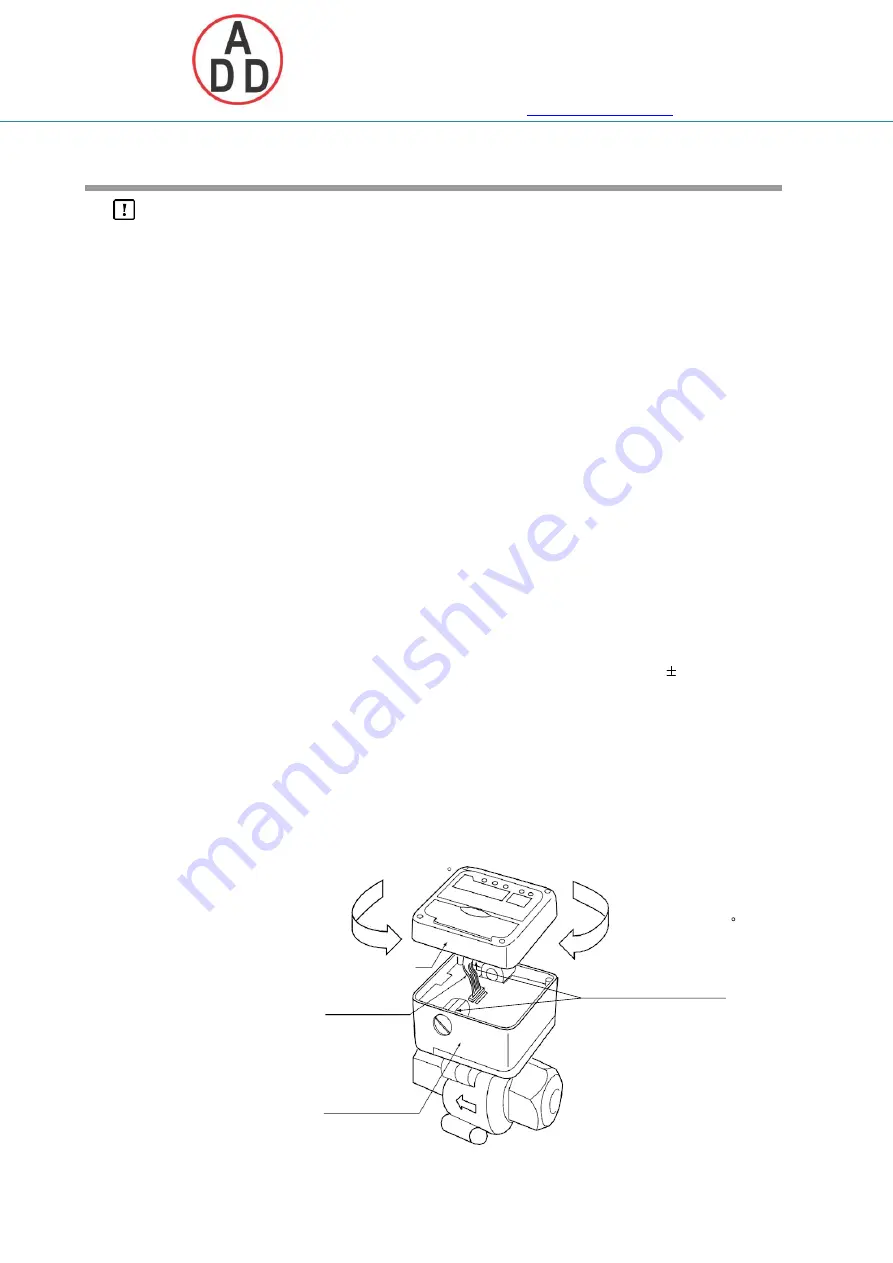

CCW rotation max. 180

CW rotation max. 180

Operation panel/

display

Connector leads

Combination No. indication

Sensor/terminal

section

Chapter 3. MOUNTING AND WIRING

Handling Precautions

• Use crimped terminal lugs, which enable a reliable connection to

terminals.

• Use crimped terminal lugs that are compatible with M3.5 screws.

• Limit the terminal screw tightening torque to 0.8N

•

m.

• Use a JIS C 3401 control cable (CVV, etc.) of maximum outer diameter

of 2.2mm for wiring.

• If waterproofing is required, be sure to use the seal connector

(Yamatake model: PA4-N2, PA4-N4 or equivalent product) for reliable

sealing.

• When wiring to terminal 2 (COM), wire the analog output lead separately

from the power lead. Otherwise, a voltage drop caused by the power

current may influence the accuracy of the analog output.

• Take care that event output 2 (the open collector output) does not

exceed the output rating of this device. When driving a relay, be sure to

use one with a built-in coil surge absorption diode. Failure to do so might

cause faulty operation.

●

Mounting the operation panel/display

On this device, the operation panel/display can be rotated up to

180˚ to an easy-

to-view position. Follow the procedure below to mount the operation

panel/display:

(1)

Connect the connectors of the leads from the operation panel/display to the

sensor/terminal section.

(2)

Rotate the display to the most easily visible position.

(3)

Fasten the operation panel/display onto the sensor/terminal section with screws.

10