AVK SEriES 29 HydrAnt

inStAllAtion, opErAtion & mAintEnAncE mAnuAl

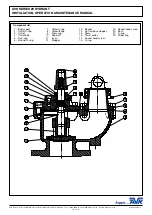

2. installation

•

When installing the valve, ensure the flange faces are clean.

•

To ensure adequate sealing it is important to select the correct type of gasket for the medium concerned, a gasket with the

correct flange size must be used.

•

Place valve onto the pipe flange, and insert the bolts.

•

Tighten bolts loosely.

•

Tighten bolts in a diagonal sequence to ensure flanges are pulled parallel.

•

Finally tighten bolts to correct torque levels as recommended in WSA 109.

2.1. Bolts

2.1.1 Bolt size

The following table shows bolt size you should use for which valve dimensions.

table B5 flanging

3. operation

This series of screw-down Squat fire hydrants are suitable for use with clean water and neutral liquids, to a maximum

temperature of 70°C. Minimum liquid temperature must be above freezing. Insulation is essential for external temperatures

on 0°C and below to a limit of -10°C. They are rated for a maximum working pressure of 16 bar unless otherwise agreed and

deliver a minimum of 2000 litres per minute at 1.7 Bar gauge.

They are normally supplied as CLOCKWISE CLOSE (CC) denoted by a WHITE plastic insert on the Stem Cap.

A CLOCKWISE TO OPEN (ACC) version is denoted by a RED plastic insert on the Stem Cap.

opEninG / cloSinG

Normally by standard ‘Tee’ Bar located on Stem Cap.

Closing Torque is 65Nm.

SWABBinG

it is not possible to use the Squat type for this purpose.

Only the

Swept

type is suitable for the introduction and retrieval of swabs.

dn

mm

Bolts

Quantity

80

M 16

4

100

M 16

4

AVK Valves Pty Ltd, 559A Grand Junction Road, Wingfield, SA 5013, Australia - T: +61 8 8368 0900 - E: [email protected] - W: www.avkcivil.com.au Version number 3

COPYRIGHT©AVK GROUP A/S 2017

pp. 4 of 6