AVK SEriES 29 HydrAnt

inStAllAtion, opErAtion & mAintEnAncE mAnuAl

4. maintenance

SAFEty prEcAutionS:

When changing obturator (stopper) and/or bonnet ‘O’ ring seal Maintenance Procedures must NOT be carried out whilst the

hydrant is installed in a live water main under pressure.

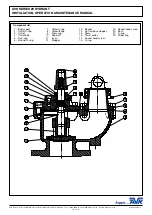

4.1. procEdurE for replacement of StEm SEAlS and polyAmid nylon BuSH

SAFEty prEcAution:

This procedure can NOT be carried out with the hydrant fully closed under pressure.

1) Remove plastic insert (11) by prising out using a thin blade.

2) Remove stem cap fixing bolt (10).

3) Remove stem cap (9).

4) Remove socket head screws (19).

5) Twist and pull the gland flange (8) upwards to remove from stem (15). Remove the ‘O’ rings (21) and Bush (20) and ‘O’

Ring (7).

6) Replace new ‘O’ rings (7) & (20) and Bush (20) by reversing operation described in clause (5). If necessary, lubricate all ‘O’

rings with an approved grease.

7) Refit socket head screws (19) torque to 15Nm.

8) Replace stem cap (9), Bolt (10) and Plastic Insert (11).

9) Open and close hydrant to check free running of stem.

4.2. procEdurE for replacement of StoppEr (oBturAtor) and BonnEt ‘o’ rinG SEAl

SAFEty prEcAutionS:

This procedure must NOT be carried out with the hydrant under pressure.

Check to ensure that there is no pressure in the main by opening the hydrant prior to commencing work.

Ensure the main will NOT be recharged before all work on the hydrant is completed.

1) Ensure hydrant is in the partly open position by turning stem cap (9) in direction indicated for opening, one or two turns to

lift stopper off seat.

2) Remove hot melt and socket head screws (17).

3) The bonnet can now be removed vertically with the stem cap (9) and stopper (12), it can be easily lifted out of the body. If

the hydrant is fitted with a loose stopper (12), this will remain on the valve seat when the bonnet is lifted out of the body

(1). Remove ‘O’ ring (6).

4) Replace ‘O’ ring (6) locating in body (1) and if necessary lubricate with an approved grease.

5) Before locating bonnet/stopper (13) into body (1), check the stopper (obturator) (12) is well up the stem (15) by 3 or 4 full

turns and ensure the stopper (obturator) guides are located to prevent the obturator turning on the stem. The stopper

(obturator) guides must both be on the same side of the body guide rails.

6) Fit bonnet (13) into Body (1) ensuring the ‘O’ ring (6) remains in position. When correctly aligned the plain face on the

bonnet (13) should be in line with the outlet.

7) Refit socket head screws (17) torque to 60Nm and fill with silicon.

4.3. procEdurE for replacement of FlAnGEd outlEt and outlEt ‘o’ rinG SEAl

SAFEty prEcAutionS:

Ensure hydrant is closed prior to commencing procedure.

procEdurE For rEmoVAl & rE-ASSEmBly:

1) Remove dust cap from outlet.

2) Remove outlet by removing 4 head head bolts.

3) To replace the outlet (3) and ‘O’ ring (2) if necessary using an approved grease then locate it in the groove in body (1).

Ensure dust cap (5) retaining ring is located in small groove on body (1) so that a bolt (4) passes through the ring. Place

outlet (3) in position, ensuring that ‘O’ ring (2) is still correctly located and tighten hex head bolts to 60Nm.

AVK Valves Pty Ltd, 559A Grand Junction Road, Wingfield, SA 5013, Australia - T: +61 8 8368 0900 - E: [email protected] - W: www.avkcivil.com.au Version number 3

COPYRIGHT©AVK GROUP A/S 2017

pp. 5 of 6