Page 16

Figure 8

6.3.2

Visual Inspection

Your Digital Nano/Nano+ is designed to automatically self-clean

calcium scale build up that may form on the blades during normal

operation. However, unbalanced water chemistry can cause a heavy

scale build up exceeding self-cleaning capabilities... thus; periodic

manual cleaning may be necessary. The simplest way to avoid this

extra work is to maintain the water chemistry at the levels

recommended.

1) The cell titanium blades, seen inside the cell body, should be straight and

clear of any debris on the ends or between the blades.

2) White flaky or crusty calcium build up on the edge or between the blades will shorten the

life of the cell. If required, clean the cell immediately, and determine the cause of scaling.

See “Basic Water Chemistry” on page 48 and “Using the Saturation Index” on page 51.

6.3.3

Manual Cleaning

WARNING:

Failure to heed the following may result in permanent injury or death.

CHEMICAL HAZARD - To avoid damaging splashes always add acid to water, never

water to acid. Wear safety glasses and use other appropriate personal protection

equipment.

CAUTION:

Failure to heed the following may result in equipment damage.

Scraping or scratching the titanium blade’s edge or surface will damage the blade

catalyst coating and cause premature failure of the cell... warranty will be voided.

Never use any sharp or metallic objects to remove scale.

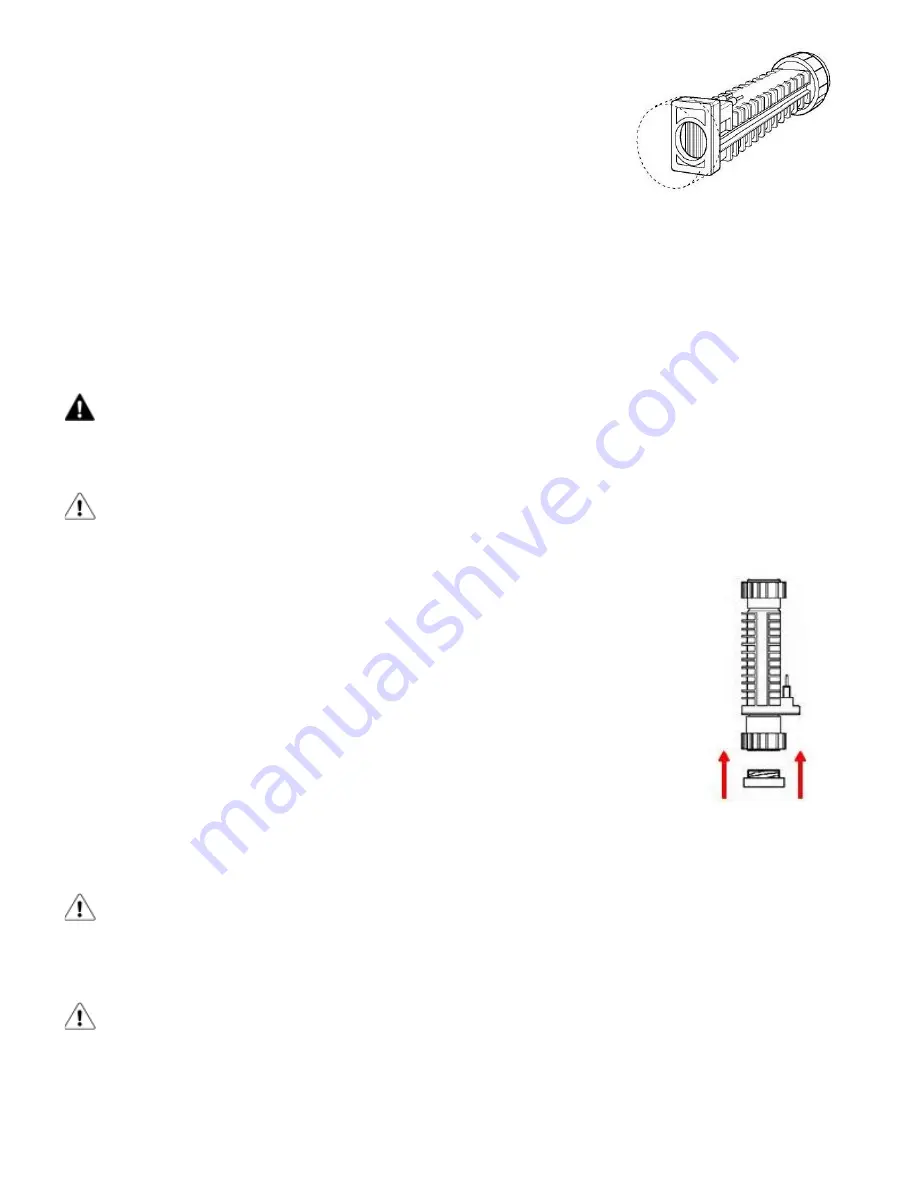

1) Place a PLA0113 cell cleaning plug (AutoPilot

®

accessory) on the end

of the cell as shown. A 1 ½” MPT clean out plug may also be used and

can be purchased in the PVC plumbing section at most pool supply or

home improvement stores.

2) Fill the capped cell with water 2 inches from the top of the cell blades.

3) Fill the rest of the cell with muriatic acid. This allows for an approximate

1-to-4 solution. Always add the acid to the water. If you do it the other

way around, it can cause the solution to spray back causing serious

injury.

4) Allow the solution to sit in the cell for 20 minutes or until the acid stops

bubbling.

5) Safely dispose of the solution; pouring it into the pool is recommended.

6) Remove the cap and rinse the cell with light water pressure; re-inspect

the cell, and repeat acid cleaning if the cell is still scaled.

6.3.4

Installing

CAUTION:

Failure to heed the following may result in equipment damage.

The Digital Nano system is to be used ONLY with a PPC1 cell. Use of any other cell

may cause equipment damage and void warranty.

The Digital Nano+ system can be used with the larger PPC2 or the smaller PPC1 cell

(It is normally shipped with the PPC2 cell).

CAUTION:

Failure to heed the following may result in equipment damage.

Ensure that cell cable is fully engaged. Partially seated cable may result in damage to

cable or cell during operation.

PLA0113 cell

cleaning plug or

1.5” MPT Plug

Figure 9

End view of the cell looking

at the blades