2.08

components

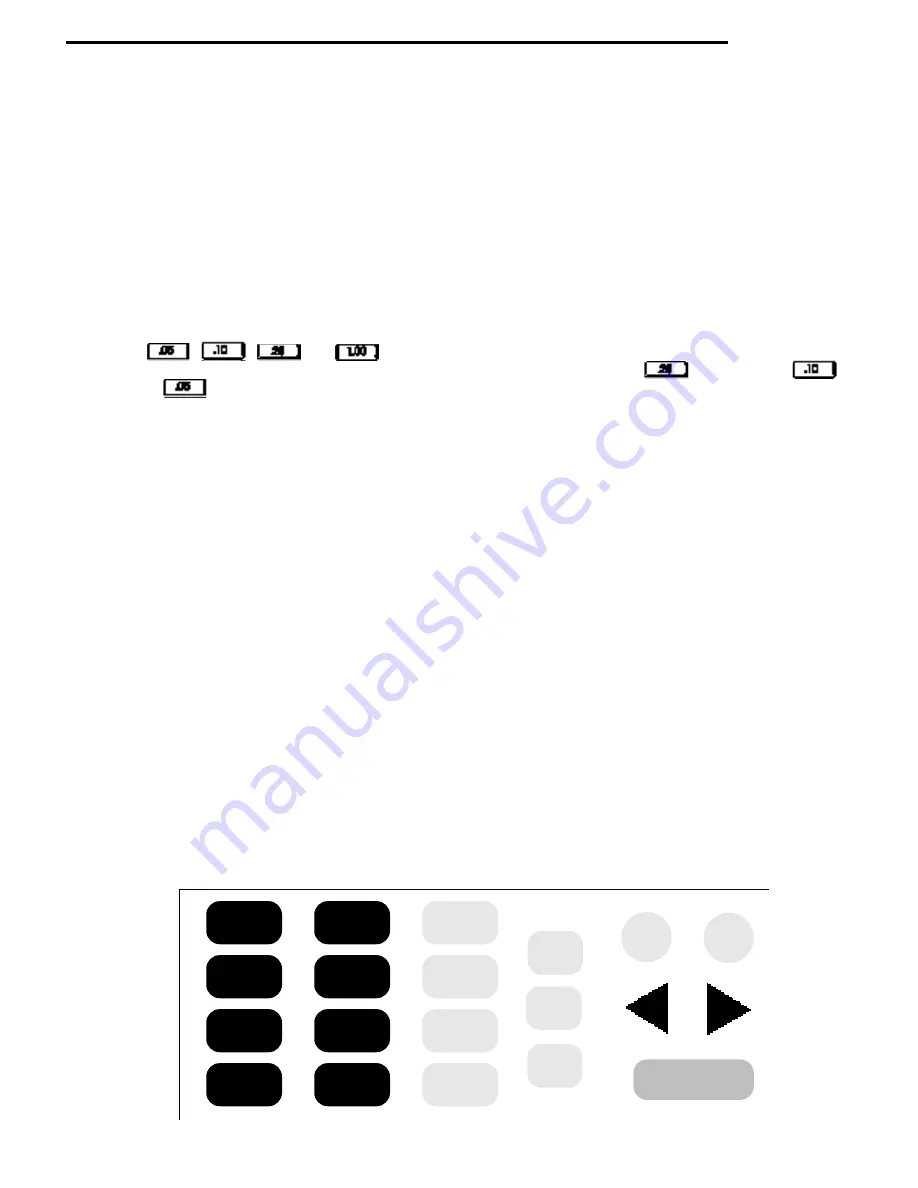

MasterMenu™ Keypad

The MasterMenu™ keypad (pictured below) is located on the front of swing out panel directly below the selection

keypad. The MasterMenu™ keypad is only active when the door is open, so even in the event of vandalism to the

control bezel, no access to the control functions is permitted.The MasterMenu™ keypad consists of seven function

buttons, a

*

key, four coin payout buttons and the eight keys used to operate the MasterMenu™ functions. The entire

keypad becomes active once the machine door is opened.

Function Buttons

The seven function keys (F1-F7) are assigned to specific pre-determined menu headings, primarily for route service

personnel. See page 4.02 for specific menu heading for each of the function keys.

Pressing the

*

key before one of the function keys

¡

through

¶

are assigned to the second level of menu headings.

Coin Payout Buttons

The four coin payout buttons are used to pay coins out of an L+ or a standard US (dummy mech).The four coin payout

buttons are , , and .The four coin payout buttons may also be used to enter pricing

information while assigning prices. For example, to enter a price of $.65, pressing the key twice, the key

once and the key once, would result in .65 appearing on the display. See the price setting section for additional

information.

The

s

key is used for exiting the current menu without making any changes prior to commitment. Note: Closing the

main cabinet door will have the same effect as if the user pressed the

s

key and causes the machine to exit the

MasterMenu™ System and return to Operational Mode.

The

e

key provides a dual purpose operation. It provides the a mechanism for entering a menu. It also provides a

means to commit insertions/modifications/deletions made in a menu item.

The

+

and

-

keys are used for incrementing and decrementing the available choices in a menu.

Note: Anywhere in this manual that the

+

or

-

keys are defined to sequence through numeric data, the front

panel may be used as an alternate input source.

The

<

and

>

keys have a dual purpose operation.They provide a means to select the menu heading immediately to

the left or right of the current menu heading.When inserting data within a menu , these keys also provide a means to

move the cursor from its current position to the position directly to its left or right.

The

y

key is used to delete the character on the current cursor position, shifting all subsequent characters to the right

of that position left by one.

The

f

key provides a mechanism to insert a character to the left of the current cursor position, shifting all characters

to the right of that position (including the current character) right by one.

Note: Depressing a function key will not cause you to enter the MasterMenu™ System.

F1

F3

F5

F7

F2

F4

F6

*

.05

.10

.25

1.00

ESC

INS

DEL

-

+

ENTER

Summary of Contents for 310

Page 45: ...section 5 parts This Page Intentionally Left Blank ...

Page 46: ...5 01 310 control module cabinet ...

Page 48: ...5 03 310 control module door ...

Page 50: ...5 05 310 swing panel ...

Page 52: ...5 07 310 board and power box assembly 21 24 ...

Page 54: ...5 09 310 power supply box ...

Page 56: ...5 11 320 inside door ...

Page 58: ...5 13 320 thermal window 4 6 2 8 5 12 10 11 14 1 15 13 7 16 3 17 18 ...

Page 64: ...5 19 320 baffle door assembly 8 7 6 6 4 3 5 2 1 10 9 11 ...

Page 66: ...5 21 320 baffle motor assembly 7 8 9 6 5 20 5 19 12 3 2 1 4 18 17 15 16 14 13 11 10 ...

Page 68: ...5 23 320 refrigeration assembly and components 7 6 5 12 10 13 1 4 3 11 8 ...

Page 72: ...5 27 320 junction box side wall mount 14 21 9 2 4 1 17 7 20 6 3 8 5 19 15 ...

Page 74: ...5 29 320 8 select spiral shelf 18 16 17 10 9 11 16 13 14 12 11 9 10 1 15 8 3 2 7 5 4 6 ...

Page 76: ...5 31 320 conveyor shelf 7 4 5 14 13 17 12 10 8 9 6 11 16 2 16 3 1 15 ...

Page 78: ...5 33 320 conveyor module 1 5 4 6 13 14 16 8 7 11 12 17 3 12 20 9 15 2 8 18 19 10 16 ...

Page 80: ...5 35 310 trim Top Trim or Trim Insert Trim Outside Vertical Trim Lower Horizontal Bottom Trim ...

Page 82: ...5 37 310 panels Lower Panel Upper Panel Top Insert ...

Page 89: ...6 01 trouble shooting chart ...

Page 90: ...6 02 trouble shooting chart ...

Page 91: ...6 03 trouble shooting chart ...

Page 94: ...6 06 electrical connections ...

Page 95: ...6 07 electrical connections P7 Default Refrigeration Jumper HI Refrigerated LO Frozen ...

Page 96: ...notes ...

Page 97: ......

Page 98: ...55 ...

Page 99: ......

Page 100: ...55 ...