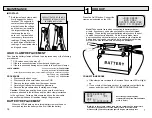

BATTERY

18

MAINTENANCE

IMPORTANT:

Both jaws of each clamp must

firmly engage the battery

terminal. The copper jaw

contains the smaller gauge

wire that reads the voltage

and the silver jaw contains

the larger conducting wire

that draws the load in

each test. Jaw insulation

is necessary for accurate

readings. Damaged clamps

or loose wires will affect the

readings. Keep clamps clean

and in good repair.

CHECK OFTEN FOR LOOSE JAWS

OR DAMAGED INTERNAL PLASTIC

SHOULDER INSULATORS

LOAD CLAMP REPLACEMENT

Over time the battery clamps will need to be replaced if any of the following

are indicated:

CCA values seem to be way off.

If there is continuity between the silver and copper jaw.

If there is excessive damage or corrosion to the cables or clamps.

PART NUMBERS:

PROCEDURE

Disconnect the back cover.

Disconnect the two small wires from the PCB.

Remove the large cables from the copper busses.

Carefully pull each wire through the grommets.

Reverse the procedure when installing new clamps.

Caution

: With cables pointing down, make sure the red clamp

wires are attached to the left buss and the black clamp is attached

to the right buss. Putting a little mineral spirits on the new cable

ends will help with ease of insertion through the grommets.

1

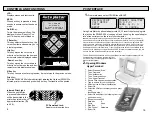

HOOK UP

Press the On/Off button: Connect the

clamps as instructed on the LCD.

Note!

Take special care when connecting to battery side ter-

minals. If necessary use a side post adapter to prevent thread

damage. When testing dual post batteries always check the post

to which the system is attached. If a load test is made from a

post connection and the alternator is mounted to side terminals a

battery load test can be completed, but a continuity problem may

still be in the side terminals when testing the alternator.

CONNECTION ERRORS

If the clamps are reversed the Reversed Connection LED will light

up.

If one or both of the clamps are not in complete contact (both the

copper and silver jaw) CHECK CONNECTIONS! will flash.

Enter the approximate battery

temperature in degrees Fahrenheit then

press (Y Enter).

Note:

Go to the setup to change temp scale to centigrade. The temperature

request only appears once for each battery tested. If the clamps are

disconnected you will be prompted again to begin a new battery test.

Positive Lead Assembly SW

458100020

Negative lead Assembly SW

458100120

Assembly includes clamp, jaws, cable, internal pick-up wire, connectors and lugs.

Black Clamp only SW

43502010

Red Clamp only SW

43501910

BATTERY REPLACEMENT

When the LCD indicates a low internal battery remove the back

cover and replace the battery with a 9 volt Alkaline battery.

JOHN DEERE

BVA 200s

SYSTEM AMALYZER

READY TO CONNECT

>ENTER BATTERY

TEMP 70F

USE +/-.

‘Y’ TO CONTINUE