- 50 -

Coupling the compressor

Now connect the compressor's connections to the

vehicle. Follow the correct sequence when making

the connections.

1. First connect the power supply and the

compressor 's ABS plug to your vehicle. Secure

these by fitting the locking bracket.

2. Clean the sealing surfaces and sealing rings of the

coupling's compressed air heads using a clean

cloth. Clean these both on the truck and

compressor.

3. Connect the compressed air line for the control

(yellow).

4. Connect the compressed air line for the feed line

(red).

Check whether the connections between the

compressor and truck are all properly connected and

closed. Remove the wheel chocks from underneath

the tyres.

Put these in their designated brackets.

Release the spindle parking brake.

Check the following before each trip:

•

Security of the wheel chocks

•

Plug and socket connections for electrics and

compressed air.

•

Functioning of light system.

•

Functioning of brake system.

•

Has the compressor been coupled properly?

•

Have the support legs been raised.

•

Is the release valve of the service brake (Button

(1) pressed) closed?

•

Is the parking brake released (Button (2) pressed)?

•

Is the ladder folded in properly?

LIFTING INSTRUCTIONS

To lift the compressor, use a lift truck or crane with

sufficient capacity (weight: see indication on

Dataplate

).

See to it that the compressor will be lifted vertically

and remains level.

(1)

P

WABCO

P

(2)

Lifting acceleration and retardation

must be kept within safe limits (max.

2xg).

Helicopter lifting is not allowed.

Lifting is not allowed when the unit is

running.

When hoisting, the apex angle of the

hoisting sling is not to exceed a

maximum of 60°.

Summary of Contents for XRVS 1350

Page 2: ......

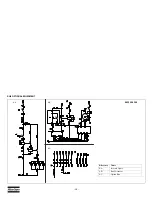

Page 24: ... 24 FLOW DIAGRAM EXHAUST AFTERTREATMENT HPFP DOC EAM DPF ...

Page 30: ... 30 SH4 COMPRESSOR CIRCUIT 9822 0963 68 ...

Page 135: ......

Page 136: ......