130

Instruction book

9096 3313 00

-

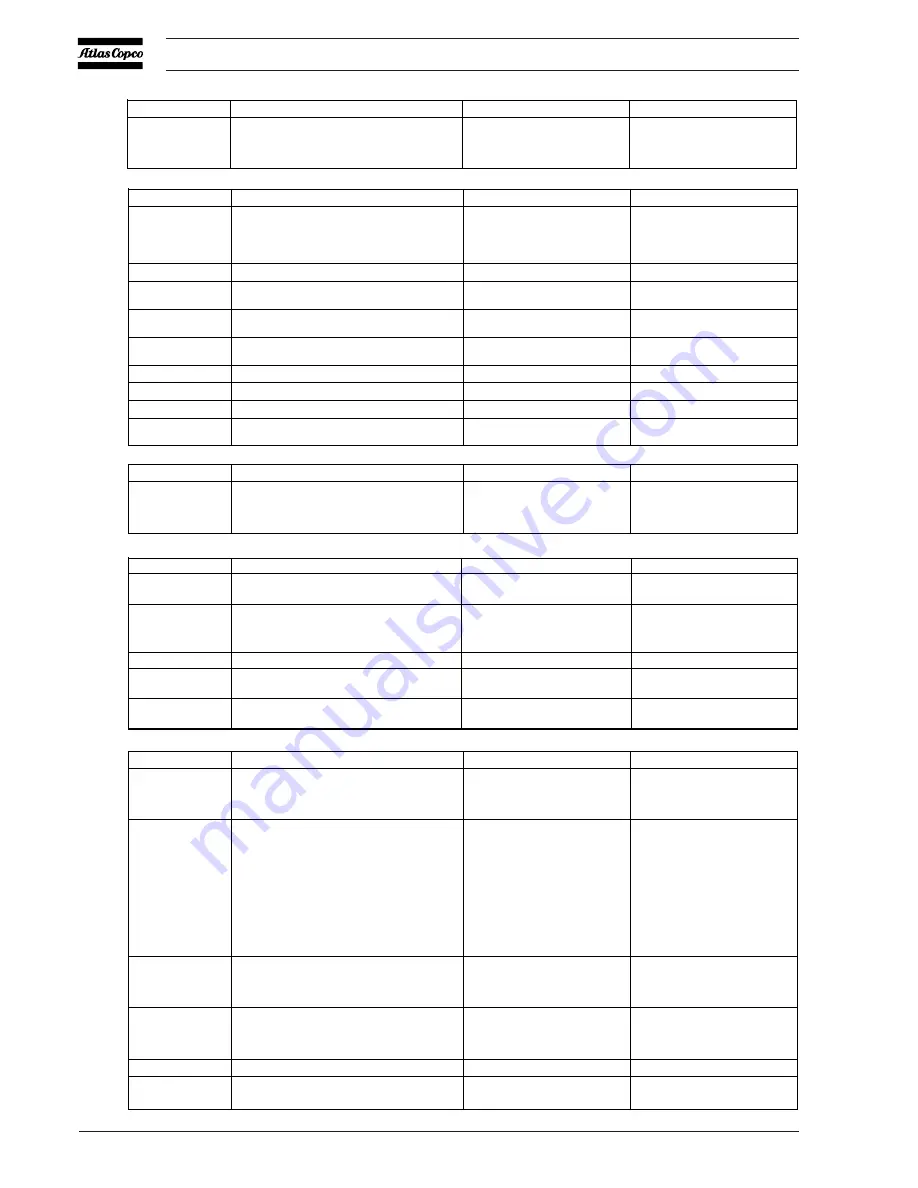

Condition

Fault

Remedy

Condensate is not discharged from

condensate separator during

loading

Discharge flexible

clogged

Check and

correct as

necessary

-

C on dition

Fau lt

R e m ed y

C o m p ress or air o u tp ut o r pres su re

b e lo w n orm al

A ir c o ns u m ptio n

exc e e ds a ir

de liv e ry o f

c om p res s or

C he ck eq uip m en t

con n ected

C ho k e d air filter e lem e n t

R ep la ce filter ele m en t

S ole n oid v a lve

m a lfun c tio n in g

R ep lac e va lv e

Le a k in c on tro l air

fle x ibl es

R ep la ce le ak in g fle xib les

In let va lv e d oe s no t fully

op e n

H av e v a lv e c he c ke d

Oil s e pa ra to r clo gg e d

H a ve e le m en t re p lac e d

A ir le ak a g e

H a ve lea k s re p aire d

S afe ty v a lve le a kin g

H a ve va lv e re p lac e d

C om p ress o r e le m en t

ou t of o rde r

C on su lt A tla s C op co

-

Condition

Fault

Remedy

Excessive oil flow through air inlet

filter after stopping

Check valve leaking

or oil stop valve

jammed

Replace defective

parts. Replace air

filter element

-

Condition

Fault

R em edy

Safety valve blows after loading

Inlet valve

m alfunctioning

Have valve checked

M inimum

pressure valve

m alfunctioning

Have valve checked

S afety valve out of order

Have valve replaced

Com pressor element out

of order

Consult Atlas Copco

Oil separator elem ent

clogged

Have elem ent replaced

-

Condition

Fault

Remedy

Compressor element outlet

temperature or delivery air

temperature above normal

Oil level too low

Check and correct

On air-cooled

compressors,

insufficient cooling air

or cooling air

temperature too high

Check for cooling air

restriction or improve

ventilation of the

compressor room. Avoid

recirculating of cooling

air. If installed, check

capacity of compressor

room fan

On water-cooled

compressors, cooling

water flow too low

Increase flow

On water-cooled

compressors, restriction

in cooling water system

Consult Atlas Copco

Customer Centre

Oil cooler clogged

Clean cooler

By-pass valve

malfunctioning

Have valve tested

Summary of Contents for GA 55+

Page 1: ...GA 55 GA 75 GA 90 Instruction book Atlas Copco Oil injected rotary screw compressors ...

Page 2: ......

Page 4: ......

Page 9: ......

Page 96: ...96 Instruction book 9096331300 6 Installation 6 1 Dimension drawings Centre of gravity ...

Page 98: ...98 Instruction book 9096331300 6 2 Installation proposal Compressor room example ...

Page 109: ...109 Instruction book 9096331300 ...

Page 123: ...123 Instruction book 9096331300 Procedure Oil system components Oil drain plugs ...

Page 145: ...145 Instruction book 9096331300 Notes ...

Page 146: ...146 Instruction book 9096331300 Notes ...

Page 147: ...147 Instruction book 9096331300 Notes ...

Page 148: ......

Page 149: ......